Die Applications Galerie bietet COMSOL Multiphysics® Tutorial- und Demo-Application-Dateien, die für die Bereiche Elektrik, Struktur, Akustik, Fluid, Wärme und Chemie relevant sind. Sie können diese Beispiele als Ausgangspunkt für Ihre eigene Simulationsarbeit verwenden, indem Sie das Tutorialmodell oder die Demo-Application-Datei und die dazugehörigen Anleitungen herunterladen.

Suchen Sie über die Schnellsuche nach Tutorials und Apps, die für Ihr Fachgebiet relevant sind. Beachten Sie, dass viele der hier vorgestellten Beispiele auch über die Application Libraries zugänglich sind, die in die COMSOL Multiphysics® Software integriert und über das Menü File verfügbar sind.

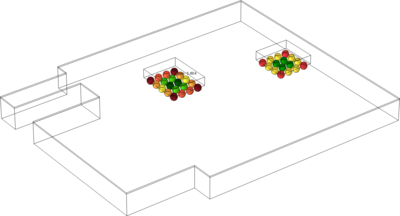

Thermal Fatigue of a Surface Mount Resistor

A surface mount resistor is subjected to thermal cycling. The difference in the thermal expansion of different materials will introduce stresses in the structure. The solder which connects the resistor with the printed circuit board is seen as the weakest link in the assembly. It ... Mehr lesen

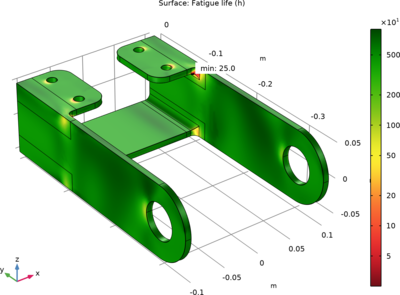

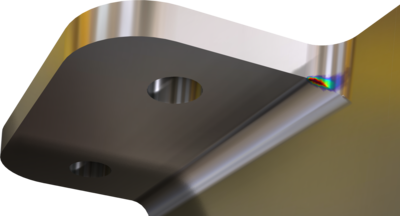

Bracket — Fatigue Evaluation

The S-N curve, also called the Wöhler curve, is one of the most popular methods for fatigue evaluation. The curve relates stress amplitude to the limiting fatigue life and can be obtained directly from a set of standard fatigue test. Many times our applications are subjected to ... Mehr lesen

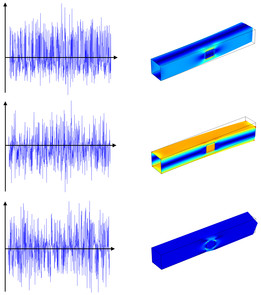

Bracket — Random Vibration Fatigue

This example shows how to perform a fatigue analysis of a structure subjected to random vibrations. Times to failure using the cycle counting models according to Bendat and Dirlik are compared. Mehr lesen

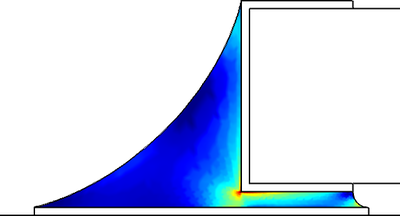

Energy-Based Thermal Fatigue Prediction in a Ball Grid Array

In a cooling system, a microelectronic component has been identified as the critical link. Since the power is repeatedly switched on and off, the component is subjected to thermal cycling. As a results a crack grows through a solder joint and disconnects the chip from the printed circuit ... Mehr lesen

High-Cycle Fatigue of a Reciprocating Piston Engine

In a reciprocating piston engine the connecting rods transfer rotating motion into reciprocating motion. The connecting rods are constantly under high stresses and the load increases with the engine speed. A failure of one part in the engine usually results in a replacement of the whole ... Mehr lesen

Fatigue Response of a Random Nonproportional Load

A thin-walled frame with a central cutout is subjected to a random load. Although the stresses are far below the yield level of the material, damage accumulates over the load history. The Rainflow counting algorithm is used to define the load scenario and Palmgren-Miner linear damage ... Mehr lesen

Standing Contact Fatigue

A standing contact fatigue test is a procedure used for testing crack growth on the subsurface level. In such a test, a spherical object is pressed against the tested materials and cycled between a high and low compressive load. No translational movement between the two occurs. After a ... Mehr lesen

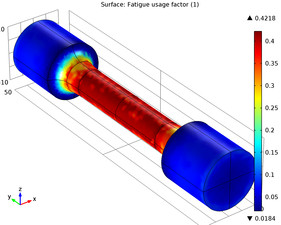

High-Cycle Fatigue Analysis of a Cylindrical Test Specimen

A benchmark model for the fatigue module. A cylindrical test is subjected to non-proportional loading. Three stress based models: Findley, Matake, Normal stress, are compared to analytical values and to each other. The non-smooth behavior of the Matake model is captured and discussed. Mehr lesen

Bracket — Harmonic Vibration Fatigue

This example shows how to perform a fatigue analysis of a structure subjected to harmonic vibrations. The loading is applied at the attachments of the structure, and a frequency sweep is performed to compute the fatigue usage. Mehr lesen

Cycle Counting in Fatigue Analysis — Benchmark

A benchmark model of the Rainflow counting algorithm compares results between ASTM and COMSOL fatigue module using a flat tensile test specimen. An extension is made for the cumulative damage calculation following the Palmgren-Miner model and results are compared with analytical ... Mehr lesen