Mechanical Behaviour of TiAl Spherical Particles Including Friction Effect

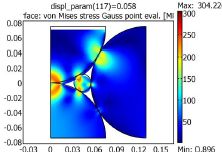

Powder metallurgy is a key technology for manufacturing advanced components based on TiAl alloys. Cold compaction is the primary step to produce green parts. Cold deformation of TiAl powder is difficult due to its typical poor ductility. Plastic deformation and cracking susceptibility of TiAl powder strongly depends on micro-mechanical phenomena. To manage real compaction problems more reliable elasto-plastic models, involving large deformation and friction at particle interfaces, are desired. The finite element method is proved to be effective in giving a quantitative prediction of the stress and strain fields provided that a reliable stress-strain curve and adequate interface conditions are introduced. To optimize the cold compaction processes of TiAl particles, a micro-mechanical elasto-plastic model is solved using COMSOL, taking into account friction effects at particle interfaces. The results are provided in terms of force-displacement curves, stress-strain distribution, contact area evolution and crack susceptibility.

Herunterladen

- maizza_paper.pdf - 0.56MB