Modeling of an industrial scale packed bed reactor for steam reforming applications.

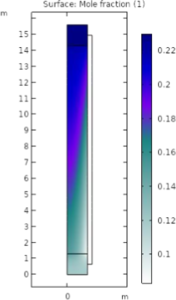

In this work, the modeling of an industrial scale, single tube, packed bed reactor for steam reforming (SR) application, typically used to provide hydrogen for ammonia synthesis, is discussed. The tightly coupled mass, energy, and momentum equations used to describe the system have been set up using the physics interfaces of the Chemical Reaction Engineering Module. Specifically, Brinkman equations, Transport of concentrated species and the Heat transfer in porous media physics have been used to describe the velocity field, gas species concentration and temperature profiles along the reactor respectively, in a stationary state 2D-axialsymmetric simulation. The Chemistry and Thermodynamics modules have also been used to consider the transport properties variation of the gas mixture due to the reaction occurring. The chemistry of SR, which typically takes place in a porous catalytic bed, has been described implementing a kinetics model widely discussed in the scientific literature. The packed bed porosity has been assumed evenly distributed as well as varying as a function of the tube radius and the catalyst particle shape/size. The energy required to drive the endothermic reaction system has been supplied through an external heat flux, provided across the tube wall, in order to analyze the heat transfer by conduction, even across the packed bed. Inlet gas composition and temperature are set at typical values of the industrial plants. The model has been applied to investigate the effect of the operating variables both on the methane mole fraction in the outlet gas stream and on the axial and radial temperature profiles along the reactor. Results are finally compared to the industrial plant data. The Model fits well with industrial data and allows a fast screening of different packed bed porosity and reaction conditions. With this information the screening of new solutions for the SR can be achieved faster.

Herunterladen

- Comsol Europe_2020_Poster_Casale.pdf - 0.35MB