Reinforcement Bars Corrosion in a Carbonated Concrete

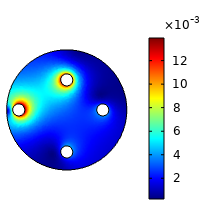

In the construction sector, the concrete and the steel bars represent still the key components, although they are very vulnerable by the atmospheric agents, as in the case of their degradation caused by corrosion. The value of the concrete carbonation may enhance the corrosion around the reinforcing bar, promoting deterioration of the mechanical properties of the material and finally of the structure. In this work we present a computational modelling work of the reinforcement corrosion in a carbonated concrete, based on experimental data obtained from a carbonation process and corrosion of the metallic bars. Using an accelerated carbonation chamber, we have carried out testing on cylindrical concrete samples reinforced with four steel bars, followed by electrochemical measurements to characterize the corrosion mechanism of the bars, which were placed at different distance from the sample external surface. The experimental data have been then introduced in COMSOL Multiphysics® to model the corrosion of the reinforcing metal under steady state conditions. Particularly, we have defined the electrochemical mechanism of the bars using the Second Current Distribution of the Corrosion Module, while the computation of the oxygen diffusion, gas required by the reduction reaction, was developed with the Transport of Diluted Species interface of the Chemical Reaction Engineering Module. The computational model was completed by incorporating the experimental kinetic data of the electrochemical electrode reactions, reflecting the carbonation front progress. Starting from the experimental values of corrosion potential, corrosion current density, anodic and cathodic slopes of the Tafel curve, the values of exchange currents have been computed and then used in the model to simulate the corrosion of the four reinforcing bars. According to the obtained results, the outward bars are characterized by stronger corrosion and reduction currents, phenomena depending also on the oxygen concentration values associated to the coupled oxygen diffusion process.

Herunterladen

- Reinforcement bars corrosion_Chiné et al.pdf - 0.69MB

- Chine_4612_presentation.pdf - 2.25MB