Transient Simulation of an Electrochemical Machining Process for Stamping and Extrusion Dies

Veröffentlicht in 2016

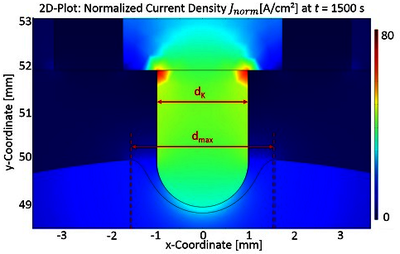

Precise electrochemical machining (PEM) is a non-conventional machining technology, based on anodic dissolution of metallic work-pieces. In this study an additional extension of the precise electrochemical machining with a precise angle-controlled cylinder positioning is aimed. Due to the help of the angle-controlled cylinder positioning, with PEM e.g. stamping and extrusion dies can be machined. To investigate the modified process transient simulation models have been developed. The models are based on the Deformed Geometry, Electric Currents and Wall Distance interfaces to compute the resulting ablation.

Herunterladen

- penzel_poster.pdf - 2.16MB

- penzel_paper.pdf - 0.62MB

- penzel_abstract.pdf - 0.16MB