Two-Scale Modeling Of The WAAM Process: Link Between Thermo-Hydrodynamics And Mechanics

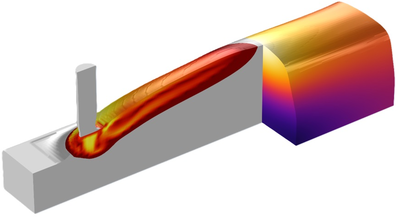

Simulation of arc-wire additive manufacturing is under development in many academic and industrial sectors and at different scales. The study at the melt pool scale is often interesting to study deposition shapes and defects but not very relevant to calculate the stresses and strains at the part scale. On the opposite, large scale mechanical modeling often relies on strong assumptions about the heat input which often generates either errors or costly and time consuming source calibration campaigns. In this presentation, we will present a multiscale approach based on a thermo-hydrodynamic calculation allowing an accurate knowledge of the temperature field. This temperature field is then directly transferred to a larger mechanical model at the scale of the part, thus avoiding the determination of an equivalent heat source. The methodology and COMSOL® tools used will be discussed on a case of manufacturing a stainless steel part

Herunterladen

- Cadiou_6151_poster.pdf - 2.45MB