Sehen Sie, wie die Multiphysik-Simulation in Forschung und Entwicklung eingesetzt wird

Ingenieure, Forscher und Wissenschaftler aus allen Branchen nutzen die Multiphysik-Simulation, um innovative Produktdesigns und -prozesse zu erforschen und zu entwickeln. Lassen Sie sich von Fachbeiträgen und Vorträgen inspirieren, die sie auf der COMSOL Conference präsentiert haben. Durchsuchen Sie die untenstehende Auswahl, verwenden Sie die Schnellsuche, um eine bestimmte Präsentation zu finden, oder filtern Sie nach einem bestimmten Anwendungsbereich.

Sehen Sie sich die Kollektion für die COMSOL Conference 2023 an

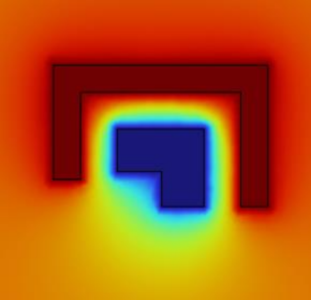

Geometry Optimization of Enzymatic Electrochemical Glucose Sensor

Diabetes is a metabolic disorder that is on a rising tide. Diabetic patients must regularly monitor their blood glucose levels. One method for designing such a device is using electrochemical principles, specifically amperometry to determine glucose concentration. It is essential to ... Mehr lesen

Improved CFD Simulation of Free Radical Polymerization in a Flow Microreactor with Additional Reaction Steps

The complete modelling of free radical polymerization (FRP) in a flow microreactor is dependent upon various transport processes - mass, momentum and heat transfer alongwith chemical reaction. And top of that, all processes are coupled to each other thus making modelling and simulation ... Mehr lesen

Numerical simulation of Proton Exchange Membrane Fuel Cells using COMSOL Multiphysics and elucidating the effect of different flow rates and temperatures

Dr. Mishma S Stanislaus1, Dr Lathapriya1, Dr Anand M Shivapuji2, Prof S Dasappa3 1 Research Scientist; 2 Senior Research Scientist; 3 Professor and Chair Interdisciplinary Center for Energy Research Indian Institute of Science; Bangalore – 560012 Proton Exchange Membrane Fuel Cells ... Mehr lesen

NUMERICAL STUDIES ON METAL HYDRIDE BASED THERMAL ACTUATORS

Smart materials, due to their ability to undergo structural and functional changes in response to external stimuli have garnered significant attention in different applications. Among these, metal hydrides have been extensively studied as potential candidates for hydrogen storage. ... Mehr lesen

In-Situ Scale Inhibitor Interaction with Surface Area of Porous Sandpack: A Numerical Approach.

ABSTRACT: Over the years, the most common method of preventing scale formation and blockage of formation pores in oil and gas systems is by squeezing of chemicals into the formation. Different experimental and simulation studies have been carried out to understand the interaction of the ... Mehr lesen

CFD modeling of a commercial CVD system and simulation of a CVD deposition process

Seco Tools produces inserts for machining metals. Roughly half the number of inserts Seco Tools produces are coated by Chemical Vapour Deposition (CVD) which extends the inserts lifetime in machining operations significantly. More than 10 000 inserts are coated on trays in each CVD run. ... Mehr lesen

Reactive Transport Modelling In Active Clays Using COMSOL Multiphysics®

The study of the movement of solutes and their interaction with the solid phase of active clays is a problem of maximum interest in various geoenvironmental engineering applications, but especially in the deep geological disposal of spent nuclear fuel and other highly radioactive ... Mehr lesen

Modeling of an industrial scale packed bed reactor for steam reforming applications.

In this work, the modeling of an industrial scale, single tube, packed bed reactor for steam reforming (SR) application, typically used to provide hydrogen for ammonia synthesis, is discussed. The tightly coupled mass, energy, and momentum equations used to describe the system have been ... Mehr lesen

Understanding the increased performance of novel interconnected-channel monolithic reactors

The versatility of the 3D printing technology has allowed developing originally structured catalysts for interesting reactions, for instance, the 0.5wt.%Fe/SiC monoliths for the treatment of industrial wastewater. These monolithic structures, manufactured by Robocasting, have ... Mehr lesen

ENGINEERING INTERCONNECTED-CHANNEL MONOLITHIC REACTORS: FROM COMSOL TO 3D PRINTING

Three-dimensional (3D) printed 0.52 wt.% Fe/SiC monoliths with interconnected channels, fabricated by direct ink printing or Robocasting, are feasible and robust catalysts for the hydroxylation of phenol to dihydroxybenzenes using hydrogen peroxide as oxidant in aqueous media [1]. ... Mehr lesen