Sehen Sie, wie die Multiphysik-Simulation in Forschung und Entwicklung eingesetzt wird

Ingenieure, Forscher und Wissenschaftler aus allen Branchen nutzen die Multiphysik-Simulation, um innovative Produktdesigns und -prozesse zu erforschen und zu entwickeln. Lassen Sie sich von Fachbeiträgen und Vorträgen inspirieren, die sie auf der COMSOL Conference präsentiert haben. Durchsuchen Sie die untenstehende Auswahl, verwenden Sie die Schnellsuche, um eine bestimmte Präsentation zu finden, oder filtern Sie nach einem bestimmten Anwendungsbereich.

Sehen Sie sich die Kollektion für die COMSOL Conference 2023 an

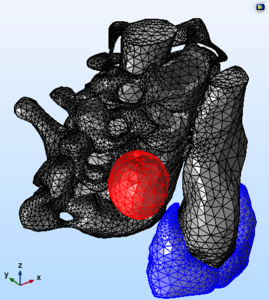

Impact of Different Modeling Approaches in Field Focusing Predictions of Hyperthermia Cancer Therapy

The hyperthermia therapy (HT), i.e. an increase of the body tissues temperature to 39-43 °C caused by the exposure to non-ionizing electromagnetic radiation (like radiofrequency or microwaves), has been demonstrated to sensitize tumours to radiotherapy and chemotherapy (i.e. cancer ... Mehr lesen

Iterative Caloric Effects Modelling Using COMSOL Multiphysics® and the LiveLink™ for MATLAB®

Scientists and engineers have been designing and developing computational tools for the numerical simulation of heat transfer processes involving non-conventional heating or cooling effects for several years. Caloric effects rely on temperature variations upon external stimuli, e.g. ... Mehr lesen

Simulation of Silver Evaporation for A Knudsen Effusion Experiment Under Zero Gravity

Material constants are required to develop new materials for the aerospace, automotive and energy industries. With these highly accurate experimentally determined data, complex metallurgical melting processes can be simulated later, for example. The microstructure of the new alloy can be ... Mehr lesen

Presumed Beta-PDF Model for the Prediction of the NOx and CO Emissions in Combustion Chambers

Optimization by means of computational tools has been stunningly useful for different industrial furnaces. However, the complexity of the equations, the wide range of characteristic times in the process, and the difficulty to extract precise enough data to model a combustion chamber ... Mehr lesen

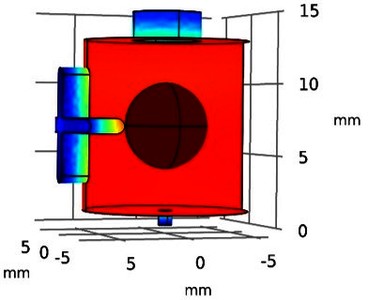

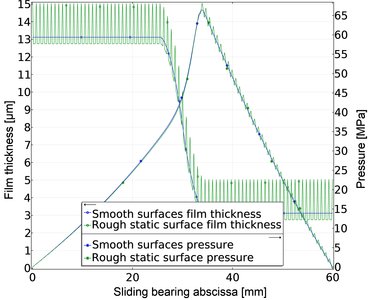

From the Laser Parameters to the Tribological Properties with COMSOL Multiphysics®

Whereas the physic models of fluid lubrication should be able to provide quantitative predictions to industrial problems, it is somehow demanding to provide the input data to feed these high-level equation systems. The operating conditions are generally available, and the material ... Mehr lesen

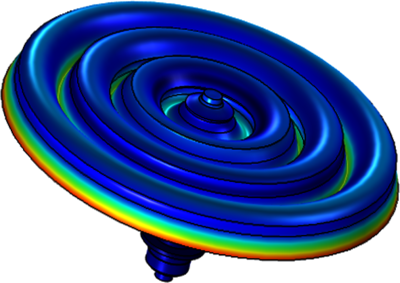

Optimization of the acoustic pressure distribution inside a freeze drying chamber

IntroductionThe application of power ultrasounds in food dehydration processes have shown a good performance in terms of efficiency, energy reduction and quality of the final product, allowing also a reduction in the convective drying kinetics, and at lower temperatures than conventional ... Mehr lesen

Numerical Optimization of the Ultrasonic Cleaning Technique for Pipelines

Fouling accumulation in pipelines is a known problem in industry which is currently treated by mechanical, hydraulic and chemical means. Each requiring a halt in the production to carry out the procedure. Industry requires a method that is non-invasive and can be used in-situ, Ultrasonic ... Mehr lesen

Coupled Electromagnetic-Thermal Model of a Superconducting Motor

The construction of a superconducting aircraft motor demonstrator is underway under ASuMED project. Magnetized stacks of commercial superconducting tapes will be applied in a rotor in place permanent magnets. The rotor will be cooled with liquid hydrogen down to approximately 20K to ... Mehr lesen

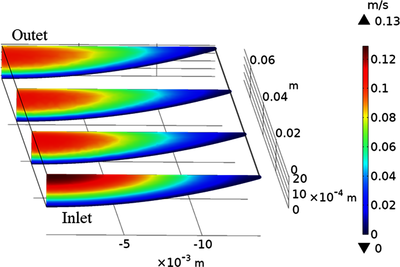

Modelling of a Thermal Time-of-Flight Sensor for Low Rate Open Channel Flow

Water transport in the public sewer system is often based on open channel flow, e.g. in a DN100 drainage pipe. Especially for low flow rates of less than 10 mL/s and with water levels of less than 4 mm, flow sensors are hardly available. In order to enable the measuring of very low ... Mehr lesen

Traveling-wave Microwave Reactor

The significance of electrification of industry increases with the growing influence of renewable electricity as a primary energy source on earth. In this sense, microwave heating is a well-established electricity-based and market-mature technology employed on the commercial scale in ... Mehr lesen