Modeling and Analysis of Aberrations in Electron Beam Melting (EBM) Systems

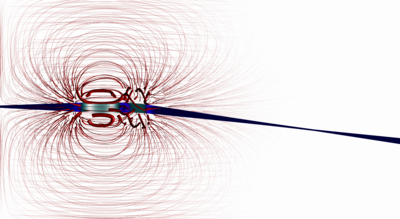

Arcam AB has pioneered additive manufacturing using the electron beam melting (EBM) technology which provides a cost efficient and novel way of producing titanium components for the orthopedic and aerospace industries. In the heart of the EBM technology is the electron beam – whose quality directly relates to the performance of the EBM machine. The beam is controlled by using magnetic lenses, which are known to cause aberrations. Inspired by the solutions used in electron microscopy, we present a modeling framework which can be used to study aberrations in an EBM system. This is achieved by using the COMSOL Multiphysics® simulation software to solve for the magnetic fields and relativistic charged particle trajectories including space charge of a model EBM system in 3D. It involves formulating a model for the magnetic lenses which performs the functions of focusing, deflecting and correcting astigmatism in the beam. For this purpose the combined capabilities of the AC/DC Module, Particle Tracing Module and LiveLink™ for MATLAB® were used running on a COMSOL Server™. The models of the magnetic lenses were designed for flexibility, with a scripted geometry as well as scripted currents allowing complex coil windings to be modeled efficiently. Methods have been developed for characterizing the beam in the model. The characterization is realized in terms of deflection angles, optical power and aberration spectra. Simulations of the magnetic fields have been made for multi-pole fields up to 24 poles. Beam parameters along with aberration analysis are presented for defocused and deflected beams. A realization of aberration correction using a superposition of a quadrupole and a hexapole in a single lens is also presented along with aberration coefficients. We conclude that higher order multi-pole lenses are necessary for improving the quality of the beam. We also discuss the practical implementation of the beam sensing necessary for determining correct aberration functions and future use of the simulation tools.

Herunterladen

- svensson_presentation.pdf - 10.81MB

- svensson_poster.pdf - 1.1MB

- svensson_paper.pdf - 7.62MB

- svensson_abstract.pdf - 0.09MB