Microscale Simulations of Catalyst Deactivation During Gas-Phase Upgrading of Biomass Pyrolysis Vapors

Catalytic fast pyrolysis is a process by which biomass may be converted into liquid hydrocarbon transportation fuels and chemical co-products that are alternative to their petroleum-derived counterparts. Chemical compounds in raw pyrolysis vapor have high oxygen content and therefore must be deoxygenated in order to meet specifications for hydrocarbon fuels. One strategy to accomplish this is to pass the vapors over a deoxygenation catalyst immediately after pyrolysis in a process called ex-situ catalytic fast pyrolysis.

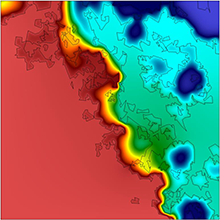

In this presentation, I will present methods to simulate catalytic upgrading and catalyst deactivation at the scale of a single catalyst particle in an ex-situ gas phase reactor. The system geometry is obtained directly from transmission electron microscopy (TEM) of the catalyst particle and imported into COMSOL Multiphysics® software using the CAD Import Module. This process is depicted in Figure 1a-c. A reaction/diffusion model, which includes a catalyst deactivation mechanism, is simulated using the Transport of Dilute Species Interface. Simulation results are shown in Figure 1 d and e. Post processing of the simulation results provides estimations of product yield and catalyst activity. These results can be used to optimize reactor conditions by identifying optimal catalyst exposure times in a given reactor configuration.

Herunterladen

- ciesielski_poster.pdf - 4.81MB

- ciesielski_abstract.pdf - 1.26MB