Transient Heating and Cooling in a Packed Bed with Fluid Flow for Controlling Solute Adsorption

We have created and optimized a multiphysics model using COMSOL Multiphysics® software that incorporates the Free and Porous Media Flow and Heat Transfer in Porous Media interfaces to simulate the temperature profile of a chromatographic system under external heating and cooling conditions.

In chromatography, a liquid mobile phase is pumped through a column containing a stationary phase made up of a packed bed of particles. The particle surface is generally covalently modified with a ligand, in this case a nonpolar 18-carbon alkylsilane. Nonpolar analytes spend more time in the stationary phase while more polar analytes spend more time in the mobile phase. These differences in polarity allow for a separation of a mixture of analytes. Decreasing column temperature typically increases adsorption of analyte to the stationary phase. Cooling the first portion of a column during sample loading causes sample concentration due to increased analyte adsorption. This portion of the column must be heated rapidly to simultaneously release all analytes which have been compressed into a small band. This compressed band then progresses to the remaining portion of the column where the separation occurs. Compared with chromatographic separations without this treatment of the first portion of the column, this procedure increases peak height and resolution between analyte bands.

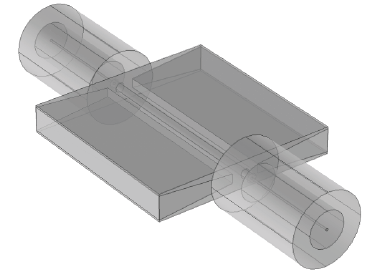

This simulation mimicked our laboratory conditions: silica capillary tubing with inner diameters ranging from 50 μm to 500 μm and stainless steel tubing with inner diameters (ID) of 1 mm, 1.5 mm, and 2.1 mm. These computations determined rates of heat flow from an external heating/cooling under conditions when the mobile phase was flowing. An array of Peltier devices is used to modify and maintain the temperature inside the column. These computations allow a determination of maximum flow rates and maximum effective packed bed diameter that would allow for a rapid temperature change. Both calculations with COMSOL Multiphysics® software and experiments prove that changing the column temperature using an external heat source is effective in all sizes of capillary and in the 1 mm ID stainless steel device.

Herunterladen

- horner_poster.pdf - 1.25MB

- horner_abstract.pdf - 0.02MB