We developed COMSOL Multiphysics to empower the engineering and science communities with state-of-the-art simulation tools. A key ingredient of this empowerment is flexibility. COMSOL users are already well aware of the full compatibility between various physics. This means you can put any (yes, really any) combination of COMSOL physics together. But that’s not the only way our multiphysics simulation tool is flexible.

Multidimensional Modeling

Another complementary type of flexibility is what I would call “multidimensional modeling”. This, of course, implies that you can model in 3-, 2-, 1, and even 0D. Even more, you can combine models across dimensions. For instance, you can solve for one physics on a boundary (2D) and use it as a condition for a 3D simulation. This approach not only saves precious computational power but also reflects the real physical effects based on where they are actually taking place. While this capability has been built into COMSOL for quite some time, it has not been among the most-used features. That might change with the release of the Pipe Flow Module.

Computational Pipe Flow the COMSOL Way

The new Pipe Flow Module automatically builds in multidimensional modeling. Here’s why: one characteristic of modeling flow in pipes is that the geometry is typically uniform along the length of a pipe. The physics of the problem can then be simplified so that its discretization results in a more efficient computation. In other words, you can make the flow along the pipe a 1D simulation. This can save hours (or more) of computation time.

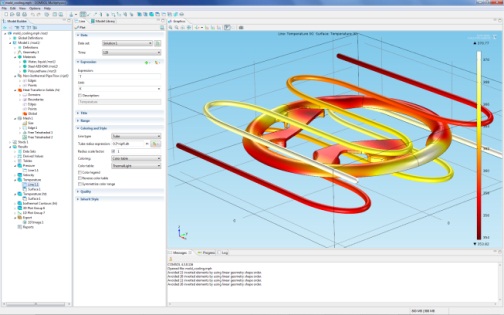

Now the real innovation here is the ability to couple back the flow in a pipe to a higher dimension model. Consider the example of the cooling of a steering wheel mold.

In this model, the curved pipes are modeled in 1D, while the steering wheel along with the surrounding mold (the box) was modeled in 3D. So as the heat flow through the pipe cools, it affects the mold and eventually the steering wheel. The results are as accurate as if you were to model the cooling pipes in 3D, yet the computational savings is two orders of magnitude. Big!

While there are other features in COMSOL that take advantage of multidimensional modeling (coupling with circuits, port conditions, laminar flow profiles, etc.), the Pipe Flow Module is the first full product that is based on this feature. I expect it won’t be the last.

There is more to the Pipe Flow Module, and I encourage you to delve into the details if you’re interested. I think it’s an important breakthrough, and now you know why.

Comments (0)