Micromechanics and Macromechanics of a Composite Cylinder

Application ID: 67001

Fiber composites are widely used in industrial applications. Compared to more traditional metallic engineering materials, fiber composites often have superior specific stiffness and strength properties, and they are often more corrosion resistant. Also, properties like strength, stiffness, and toughness can often be tailored to specific applications. A fiber composite consists of load carrying fibers embedded in a polymer resin. The composite material is typically a laminate of individual layers, where the fibers in each layer are unidirectional. This model demonstrates how to perform a stress analysis of a laminated composite cylinder.

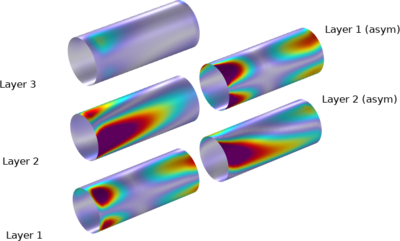

Modeling individual fibers in every layer in the laminate is unfeasible. A simplified micromechanics model of a single carbon fiber in epoxy is instead used to estimate the homogenized elastic properties of a single layer. These properties are then used in the macromechanical model of the laminated composite cylinder. Two approaches are used to model the laminate, namely the Layerwise (LW) theory and the Equivalent Single Layer (ESL) theory.

Dieses Beispiel veranschaulicht Anwendungen diesen Typs, die mit den folgenden Produkten erstellt wurden:

Allerdings können zusätzliche Produkte erforderlich sein, um es vollständig zu definieren und zu modellieren. Weiterhin kann dieses Beispiel auch mit Komponenten aus den folgenden Produktkombinationen definiert und modelliert werden:

Die Kombination von COMSOL® Produkten, die für die Modellierung Ihrer Anwendung erforderlich ist, hängt von verschiedenen Faktoren ab und kann Randbedingungen, Materialeigenschaften, Physik-Interfaces und Bauteilbibliotheken umfassen. Bestimmte Funktionen können von mehreren Produkten gemeinsam genutzt werden. Um die richtige Produktkombination für Ihre Modellierungsanforderungen zu ermitteln, lesen Sie die Spezifikationstabelle und nutzen Sie eine kostenlose Evaluierungslizenz. Die COMSOL Vertriebs- und Support-Teams stehen Ihnen für alle Fragen zur Verfügung, die Sie diesbezüglich haben.