Die Application Gallery bietet COMSOL Multiphysics® Tutorial- und Demo-App-Dateien, die für die Bereiche Elektromagnetik, Strukturmechanik, Akustik, Strömung, Wärmetransport und Chemie relevant sind. Sie können diese Beispiele als Ausgangspunkt für Ihre eigene Simulationsarbeit verwenden, indem Sie das Tutorial-Modell oder die Demo-App-Datei und die dazugehörigen Anleitungen herunterladen.

Suchen Sie über die Schnellsuche nach Tutorials und Apps, die für Ihr Fachgebiet relevant sind. Beachten Sie, dass viele der hier vorgestellten Beispiele auch über die Application Libraries zugänglich sind, die in die COMSOL Multiphysics® Software integriert und über das Menü File verfügbar sind.

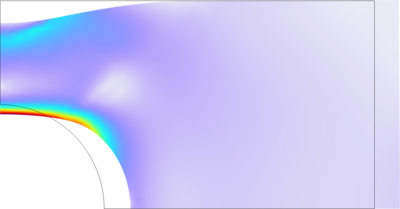

In this example, wrinkling is studied in a cylindrical membrane of nonuniform thickness under axial and pressure loading. The membrane is modeled as an incompressible Mooney–Rivlin material. During axial stretching, certain portions of the membrane undergo wrinkling; however, the ... Mehr lesen

Drop tests are used to evaluate how consumer products respond to impacts and high accelerations. In this example, the Solid Mechanics, Explicit Dynamics interface is used to numerically simulate a drop test of a mobile phone, highlighting the permanent deformation of the aluminum case ... Mehr lesen

In this tutorial model, it is demonstrated how to incorporate a localized nonlinearity in a submodel. In this case, an initial elastic analysis reveals that a small region of a structure has stresses above the yield limit. To improve the results, an elastoplastic material model is added ... Mehr lesen

Creep is an inelastic time-dependent deformation which occurs when a material is subjected to stress at sufficiently high temperature, say 40% of the melting point or more. Experimental creep data (using constant stress and temperature) often display three different types of behavior ... Mehr lesen

This example shows the analysis of a perforated plate loaded into the plastic regime. Part of the example is a benchmark, which you can find in section 7.10 of The Finite Element Method by O.C. Zienkiewicz. The unloading of the plate and residual stresses are also studied. In a second ... Mehr lesen

In this example, the Bergstrom–Bischoff material model is used to model the temperature and strain dependent behavior of High Density Polyethylene (HDPE) used, for example, to make liners for damaged pipes in oil and gas applications, or to make type IV hydrogen storage vessels for fuel ... Mehr lesen

The fabrication of a cup through powder compaction is simulated in this tutorial model. The powder compaction process is becoming common in the manufacturing industry, due to its potential for producing components of complex shape and high strength. Combining the Fleck–Kuhn–McMeeking ... Mehr lesen

In this example, the Bergstrom–Boyce material model is used to capture the nonequilibrium behavior of carbon-black-filled chloroprene rubber under a strain history that alternates compression with relaxation. Results are verified against experimental and numerical results taken from ... Mehr lesen

The powder compaction process is becoming common in the manufacturing industry, thanks to its potential to produce components of complex shape and high strength. In this example, the compaction of iron powder to form an axisymmetric rotational flanged component is analyzed with capped ... Mehr lesen

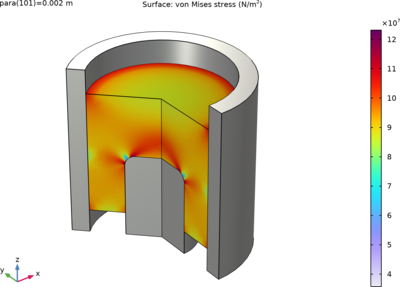

This model shows how to combine different types of material nonlinearity, such as creep and elastoplasticity. In this specific example you will perform a stress and nonlinear strain analysis on a thick cylinder under a nonproportional loading: an initial temperature increase followed by ... Mehr lesen