Sehen Sie, wie die Multiphysik-Simulation in verschiedenen Branchen eingesetzt wird

Multiphysik-Modellierung und -Simulation treiben Innovationen in Industrie und Wissenschaft voran – wie die zahlreichen Anwendungsbeispiele zeigen, die jedes Jahr in den Fachbeiträgen und Postern von Ingenieuren, Forschern und Wissenschaftlern auf der COMSOL Conference vorgestellt werden. Lassen Sie sich von den unten aufgeführten aktuellen Beiträgen inspirieren oder nutzen Sie die Schnellsuche, um eine bestimmte Präsentation zu finden oder nach Anwendungsbereich oder Konferenzjahr/-ort zu filtern.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

Materials such as aluminium with high thermal and electrical conductivities are of industrial interest, particularly for the automotive industry in the current context of increasing production of electric vehicles. The reflective properties of this material make it difficult to process ... Mehr lesen

Arc welding is a widely used process in heavy industry for the assembly of metallic components. To ensure high-quality welds, it is essential to understand both the welding process and the complex interactions within the melt pool. Numerical simulation is employed as a predictive tool to ... Mehr lesen

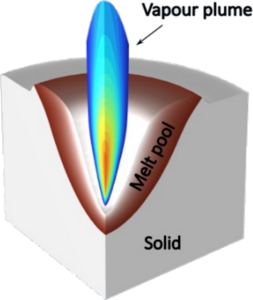

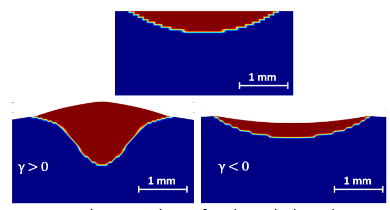

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. As it is a blown powder process, here a melt pool formation & fusion by moving the laser beam, into which powder is blown and molten & surface tension gradient ... Mehr lesen

Laser technologies such as welding, cutting and metal deposition are widely used in the industry. High quality requirements regarding process products cause that there is often a need to monitor the process. For this purpose, optical sensors integrated with a laser head are often used. ... Mehr lesen

Abstract: The electric field and temperature are the two important factors that influence the fiber diameters and properties in the melt electrospinning process. It is commonly known that the polymer jet behavior is governed by the electric field within spinning area. In the present ... Mehr lesen

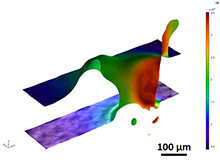

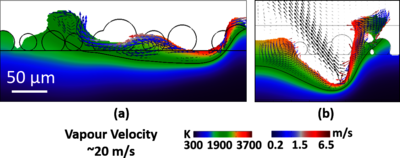

Laser material processing at micro-meter domain can be used for a plethora of applications such as micro drilling, micro welding, micro cutting, micro-texturing as well as micro polishing. These processes are governed by the time varying, complex melt hydrodynamics courtesy of melting ... Mehr lesen

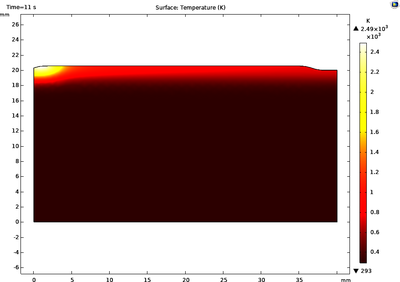

This study explores the significance of the recoil pressure, Marangoni convection and surface tension effects in selective laser melting of Ti-6Al-4V. A pragmatic two dimensional model with appropriate powder distribution over a substrate of finite thickness has been developed in COMSOL ... Mehr lesen

During the last decades, mid-IR (3-12µm) laser sources have attracted attention due to their potential applications in different fields like infrared counter-measures (e.g: missile jamming) and remote chemical sensing. In this context, Onera has been working on the development of non ... Mehr lesen

Laser-Heated Pedestal Growth (LHPG) is a crystal growth technique that employs a focused laser beam to melt a source material, creating a molten zone that is precisely controlled to produce high-quality single crystals. This method is particularly advantageous for growing crystals with ... Mehr lesen

Thermocouples are widely used in industry for process temperature measurement. Calibration drift is a well-known problem which adversely affects process control, particularly in harsh environments (e.g. high temperature). To overcome this, a mechanism for self-calibration of ... Mehr lesen