Neuerungen im Chemical Reaction Engineering Module

Für Nutzer des Chemical Reaction Engineering Module bietet COMSOL Multiphysics® Version 6.4 Unterstützung für reaktive Strömungen mit Large Eddy Simulation (LES), Modellierung von Partikelaggregation und Zerfall sowie ein neues Feature für den kontinuierlichen Betrieb mit Festphasenverbrauch und Bettnachfüllung. Weitere Informationen zu diesen Updates finden Sie unten.

Large Eddy Simulation (LES) für Reacting Flow

Das Feature Reacting Flow unterstützt nun LES und ermöglicht eine beispiellose Genauigkeit bei der Modellierung turbulenter Reaktionssysteme. Durch die Kopplung von LES mit den Interfaces Chemistry, Chemical Species Transport und Heat Transfer in Fluids können Sie die detaillierten Wechselwirkungen zwischen Vermischung, Wärmetransport und chemischen Reaktionen in Gasen und Flüssigkeiten erfassen. Der Ansatz berücksichtigt Reaktionswärme, Enthalpiediffusion und Massenflüsse, während die residuenbasierte LES-Modellierung die Vorhersagen des Wärme- und Stofftransports verbessert. Mit temperaturabhängigen Fluid- und chemischen Eigenschaften bietet diese Funktionalität äußerst realistische Einblicke in Konzentrations-, Reaktionsgeschwindigkeits- und Temperaturfelder. Unabhängig davon, ob Sie katalytische Reaktoren oder komplexe Mischprozesse untersuchen, helfen LES-basierte Modelle für reaktive Strömungen dabei, wichtige Details aufzudecken, die herkömmliche Turbulenzmodelle möglicherweise übersehen. Für die LES-Funktionalität ist das CFD Module erforderlich.

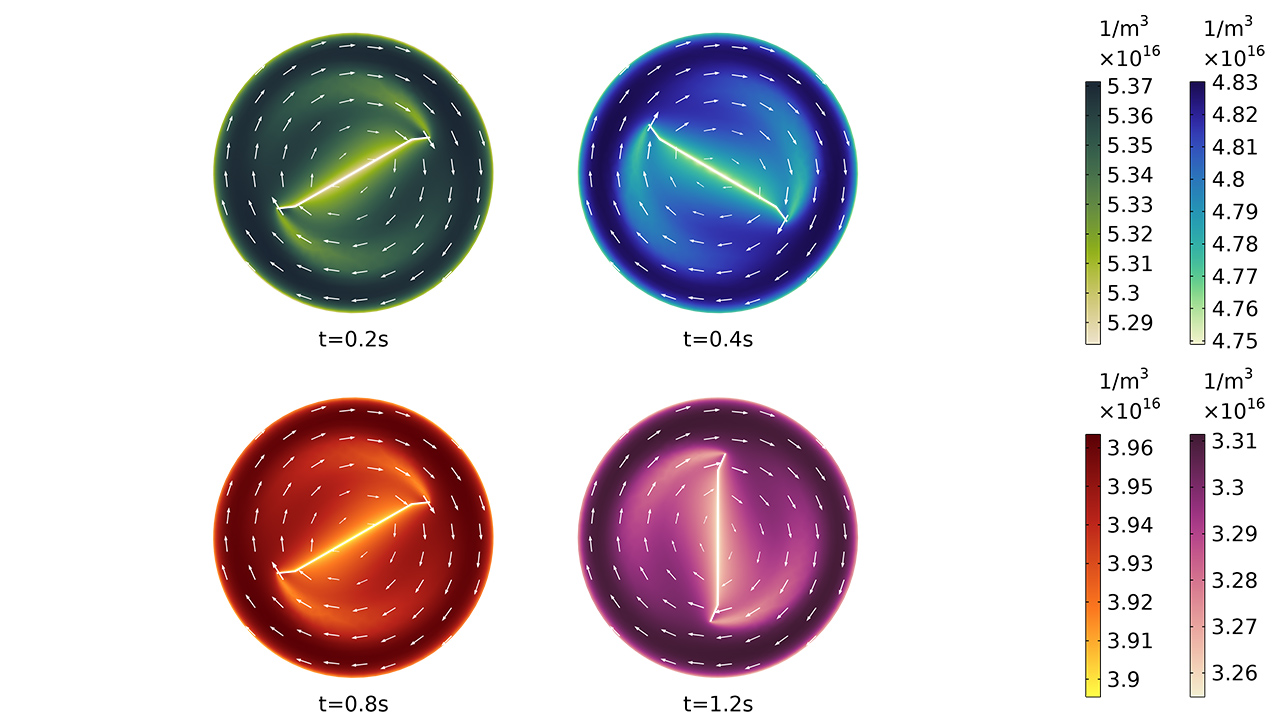

Partikelaggregation und Zerfall

Von der pharmazeutischen Herstellung bis hin zur Verarbeitung fortschrittlicher Werkstoffe ist die genaue Modellierung von Partikelwachstum, Morphologie und Zerfall für die Prozessoptimierung von entscheidender Bedeutung. Die neue Unterstützung für Partikelaggregation und Zerfall ermöglicht eine realistische Simulation der sich entwickelnden Partikelgrößenverteilungen in Kristallisations-, Fällungs- und Granulationsprozessen. Diese Funktionalität ist im Interface Precipitation and Crystallization implementiert, das nun die Smoluchowski-Koagulationsgleichung zusammen mit einer Fragmentierungsgleichung löst, um eine genaue Beschreibung der Partikeldynamik zu liefern.

Feature für Reaktoren mit beweglichem Bett

Eine neue Feature für Reaktoren mit beweglichem Bett ermöglicht die Modellierung heterogener Reaktoren, in denen die feste Phase kontinuierlich verbraucht und wieder aufgefüllt wird. Diese Feature ermöglicht detaillierte Untersuchungen von Prozessen, bei denen die Bewegung des Bettes einen starken Einfluss auf die Reaktoreffizienz hat, wie beispielsweise katalytisches Cracken, Gas-Feststoff-Reaktionen und die Umwandlung von Biomasse. Die Feature berücksichtigt das dynamische Verhalten der festen Phase während des kontinuierlichen Betriebs und ist damit eine leistungsstarke Option für die Analyse von Effizienz, Selektivität und Betriebsbedingungen in industriellen Prozessen.

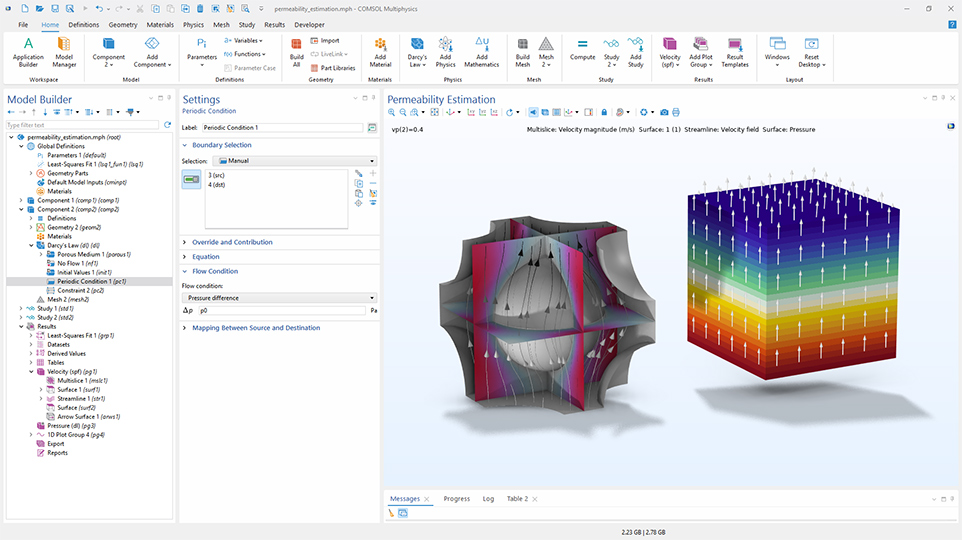

Periodic Condition

Die Interfaces Darcy's Law und Richards' Equation enthalten jetzt das neue Feature Periodic Condition, mit dem sich die Periodizität der Strömung zwischen zwei oder mehr Rändern festlegen lässt. Darüber hinaus ist es möglich, einen Druckunterschied zwischen Quell- und Zielrand zu erzeugen, indem entweder der Drucksprung direkt angegeben oder ein Massenstrom vorgegeben wird. Das Modell Estimating Permeability from Microscale Porous Structures veranschaulicht dieses neue Feature. Periodic Condition wird in der Regel verwendet, um repräsentative Volumenelemente zu modellieren und effektive Eigenschaften für die Verwendung in homogenisierten porösen Medien zu berechnen.

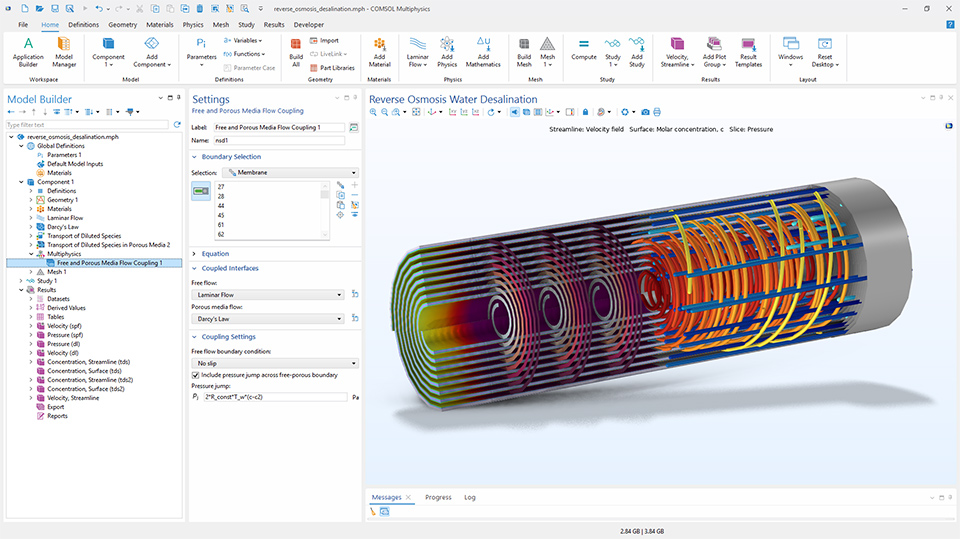

Drucksprungoption für Free and Porous Media Flow Coupling

Free and Porous Media Flow Coupling verfügt über eine neue Option, um einen Drucksprung über die Grenze zwischen freiem und porösem Medium hinweg einzubeziehen. Damit lassen sich beispielsweise der osmotische Druck an einer semipermeablen Membran, die von einem porösen Abstandsmaterial gestützt wird, oder ein Drucksprung aufgrund des Kapillardrucks bei einer Mehrphasenströmung modellieren. Das Tutorial-Modell Reverse Osmosis Water Desalination tutorial model veranschaulicht diese neue Option.

Neue und aktualisierte Tutorial-Modelle

COMSOL Multiphysics® Version 6.4 enthält mehrere neue und aktualisierte Tutorial-Modelle für das Chemical Reaction Engineering Module.

Production of Antibody–Drug Conjugates in a Stirred Tank Reactor

Simulation einer turbulenten reaktiven Strömung in einem Tankreaktor mit einem vierflügeligen Rührer. Isosurfaces und Konturen der konjugierten Antikörperkonzentration liefern wertvolle Erkenntnisse über die Mischeffizienz und Reaktionsleistung.

Chemical Vapor Deposition of Titanium Nitride on Machining Tool Inserts

Turbulent Aggregation of Nanoparticles

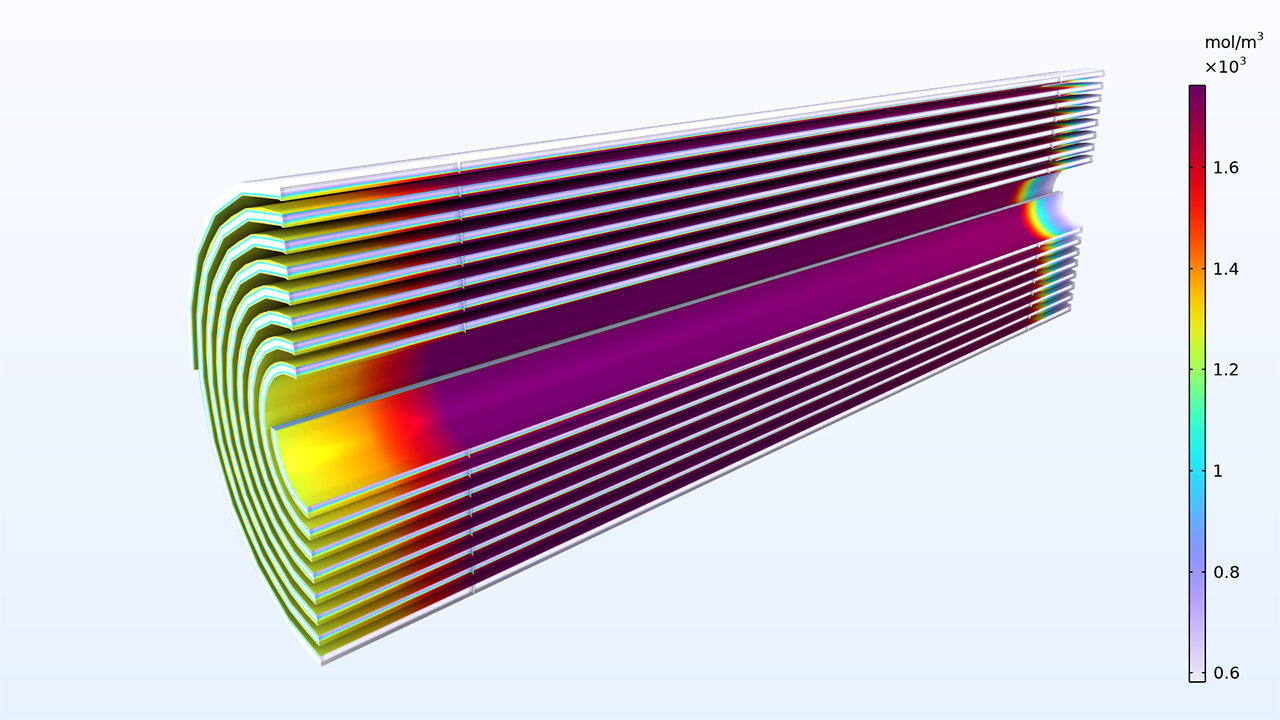

Charging of a Metal Hydride Tank

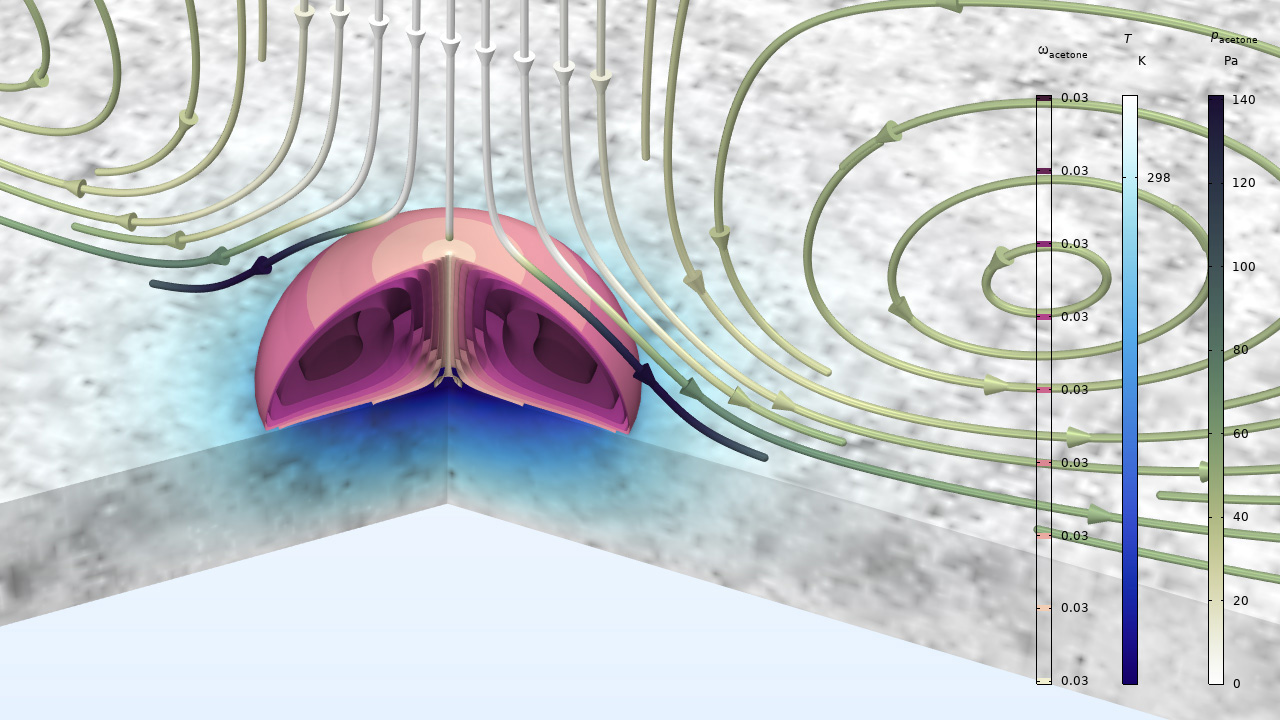

Convective Evaporation of a Water–Acetone Droplet

Reverse Osmosis Water Desalination