Pulse Reverse Plating

Application ID: 61601

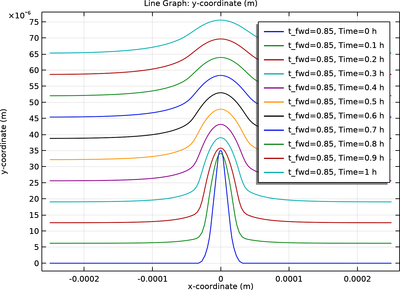

This tutorial explores how pulse reverse plating can be used as an additive-free alternative to attenuate small protrusions during copper metal deposition. By matching the process parameters, including the length of the forward and reverse pulses (duty cycles), a bright mirror-like metal surface can be created.

The model assumes that a quasi-stationary current distribution establishes quickly during each pulse, so that an average of the forward and reverse deposition rates can be used in the time-dependent deforming geometry simulation.

Dieses Beispiel veranschaulicht Anwendungen diesen Typs, die mit den folgenden Produkten erstellt wurden:

Allerdings können zusätzliche Produkte erforderlich sein, um es vollständig zu definieren und zu modellieren. Weiterhin kann dieses Beispiel auch mit Komponenten aus den folgenden Produktkombinationen definiert und modelliert werden:

- COMSOL Multiphysics® und

- entweder Battery Design Module, Corrosion Module, Electrochemistry Module, Electrodeposition Module, oder Fuel Cell & Electrolyzer Module

Die Kombination von COMSOL® Produkten, die für die Modellierung Ihrer Anwendung erforderlich ist, hängt von verschiedenen Faktoren ab und kann Randbedingungen, Materialeigenschaften, Physik-Interfaces und Bauteilbibliotheken umfassen. Bestimmte Funktionen können von mehreren Produkten gemeinsam genutzt werden. Um die richtige Produktkombination für Ihre Modellierungsanforderungen zu ermitteln, lesen Sie die Spezifikationstabelle und nutzen Sie eine kostenlose Evaluierungslizenz. Die COMSOL Vertriebs- und Support-Teams stehen Ihnen für alle Fragen zur Verfügung, die Sie diesbezüglich haben.