Comparison of Dispersion Model for Spheres of Varying Geometry

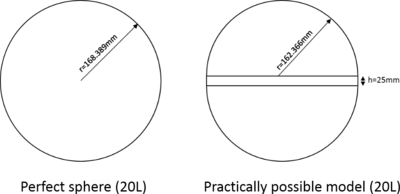

Manufacturing of an apparatus for experimental purpose pose certain difficulties due to the process involved. For a 20L perfect sphere, manufacturing by forging or any other process is not economical, due to which the equipment is manufactured with modified dimensions. This paper aims to investigate the explosion behaviour affected by the changes in designs of explosion vessels. Our aim is to understand the diversion of dispersion model in a vessel manufactured with joining 2 hemisphere with a cylindrical joint, compared to perfect sphere using CFD analysis and tools available in COMSOL. The width of cylindrical portion will be 25 mm and its volume 2.0705L, to compensate for this additional volume, we need to reduce the radius of sphere by 6.023mm. Thus reducing the uniformity in the dispersion. Inlet will be set at the geometric center for both the shapes at a very high pressure of 2*106 Pa, as we do not have a direct module in COMSOL to simulate explosion and dust dispersion. Model of fluid flow under turbulent conditions will be considered and effect of pressure and velocity changes with respect to time will be identified. The study involves studying various characteristics for a dust explosion apparatus, when the explosion is modelled as a single phase turbulent flow. COMSOL Multiphysics was used to obtain various characteristics of the undertaken study, and numerical results are computed using the Algebraic yPlus model. It was ensured that the particles are taking the necessary path while entering the explosion vessel and are well dispersed within the constricted area. Pressure profiles, impact of pressures on the vessel wall, as well as on the joints, velocity profiles, path taken by particles within the shell, thickness of the shell, are some of the parameters which were studied. Velocity profiles as well as the particle path are critical parameters which affect the mechanism of combustion. Determining the zones of turbulence was an imperative part of this study.

Herunterladen

- COMSOL_Bangalore_2019_SoumaDhar.pdf - 0.26MB