Electromagnetic Sensing System for Ore Waste Classification and Grade Detection in LHD Buckets

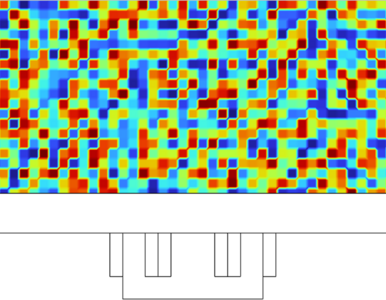

Underground mines that employ the sublevel caving (SLC) method often suffer from significant levels of ore dilution due to the technique of extracting ore through gravity flow. When the ore is blasted and falls into drifts, it creates the drawpoints where Load-Haul-Dump (LHD) vehicles collect the fragmented material and transport it to its destination or a subsequent transportation system. LHDs are equipped with a hydraulic sensor in their arm to measure the weight of the material in the bucket. With the weight of the material, it is possible to both distinguish between waste material and ore, due to the different rock properties, and approximate the ore grade of the load. However, this measurement presents challenges when, for example, both rocks have similar density, or when filled volume, fragmentation, and water content vary significantly in each load operation. This lack of material discrimination leads to increases in operational cost, inefficiencies in material transportation, and energy waste. The study focuses on the Kiirunavaara mine case and investigates the feasibility of an electromagnetic sensing system concept for the LHD bucket, capable of distinguishing between magnetite-rich iron ore and waste based on their intrinsic electromagnetic properties. This work focuses on modeling a sensing system using the AC/DC module of COMSOL Multiphysics® software. The problem setup includes a 3D model of an LHD bucket partially filled and a sensor array composed of excitation and detection coils placed along the outer bucket walls. A primary magnetic field and a resulting induced field are monitored to evaluate differences in magnetic flux density and eddy current distribution, to distinguish ore from waste, and to approximate ore grade. Simulations suggest that the sensor system is susceptible to the spatial arrangement of ore versus waste inside the bucket. Specifically, the presence of high-permeability zones (iron ore) results in significant contrasts in magnetic field intensity and distribution patterns. In addition, results support the feasibility of the technique to infer average ore grade immediately after loading and lay the groundwork for a future prototype validation. If successful, this system could contribute to smarter underground operations, real-time material classification, and reduced dilution.