Modeling to design novel thermoelectric-based heat exchanger for liquid foods pasteurization

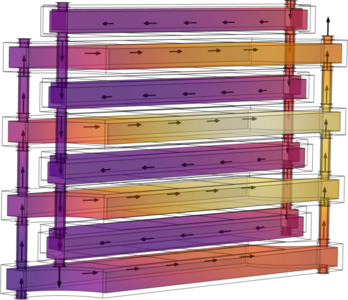

The High-Temperature-Short-Time (HTST) heat exchanger is widely used for pasteurizing liquid foods such as milk and juice. It relies on steam for heating and cold water for cooling via passive heat transfer, resulting in high energy consumption. This study proposes a ThermoElectric (TE)-based heat exchanger as an electrified, energy-efficient alternative to the HTST system. The TE system eliminates the need for steam, reduces system complexity and pumping, and enables active thermal energy recovery using TE devices. To develop this technology, COMSOL Multiphysics was used to simulate the TE heat exchange process and evaluate different designs to optimize system performance and energy efficiency. The TE heat exchanger combines multiple complex processes: heat generation and pumping within TE devices, heat transfer in the solids of exchanger plates and the liquids of raw and pasteurized foods, and fluid flow of the liquid food between the exchanger plates. Maximizing energy efficiency requires optimizing both the TE devices' performance and the fluid pumping efficiency. Based on COMSOL’s TE cooling model and commercial TE device data, maintaining a small temperature difference across the two sides of TE device is crucial for high efficiency. In terms of fluid dynamics, the design configuration significantly affects pressure drop and pumping energy. To design a TE heat exchanger with overall energy efficiency, two TE heat exchanger models were developed: parallel and series connections. In the parallel configuration, multiple TE devices are stacked in layers with alternating heating and cooling fluid flow channels in between. The liquid food is heated and cooled after passing of TE devices with many turns. This design maintains a small temperature difference between two sides of the TE devices, improving energy recovery. However, it requires complex flow paths and higher pumping energy. In a series connection, multiple TE devices are connected in series as a TE plate, and the fluid is heated and cooled after a single pass on two sides of the TE plates. This reduces fluid friction and pumping energy but demands careful control of temperature gradients across each TE unit to maintain TE efficiency. To evaluate the two TE heat exchanger designs, two 3-dimensional models with heat exchanger plates and fluid flow domains were created. The geometry of the TE devices was not created in detail to reduce the computational requirement. Instead, an analytical model that estimated the heat transfer flux of TE devices was developed and integrated with COMSOL as boundary conditions through LiveLink for MATLAB. The COMSOL models also integrated modules of CFD and Heat Transfer to simulate the TE heat exchange process to evaluate the thermal and pumping energy requirements. The modeling results showed that both parallel and series connections of TE devices can achieve the desired heating and cooling processes for liquid food pasteurization with better energy efficiency than the HTST system. The series connection needs less pumping energy due to the reduced fluid friction, indicating better overall system energy efficiency. The simulation results demonstrated the feasibility of the TE heat exchange technology that will provide a significant impact on the food industry.

Herunterladen

- SaharSaadat-2025-Slideshows.pptx - 7.82MB

- SaharSaadat-2025-Poster.pptx - 1.39MB