Simulative Development of a Convectively Cooled Heat Sink for a Heat Pipe Mould-Element

Simulative Development of a Convectively Cooled Heat Sink for a Heat Pipe Mould-Element

Corresponding Author: mhuettemann@fh-bielefeld.de

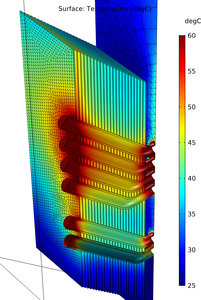

The FH Bielefeld has developed an injection mold in which a lateral slide is tempered by heat pipes instead of conventional cooling channels. The heat sink is to be convectively cooled by a fan which blows an airstream against a fin package. The amount of heat to be dissipated is determined by idealized source and sink temperatures. Which are experimentally determined in a three-dimensional plot of the heat transfer capacity of each heat pipe. To reduce the number of design loops on the real heat sink, COMSOL Multiphysics® is used to investigate the optimal number, arrangement and geometric design of the fins. Here, the results of the built-in convective heat flow boundary conditions are compared with the multiphysics coupling "Non-Isothermal Flow" between "Heat Transfer in Solids" and "Laminar Flow".

Herunterladen

- 2020_Poster_Comsol.pptx - 0.46MB