Single-Phase Modeling in Microchannel with Piranha Pin Fin

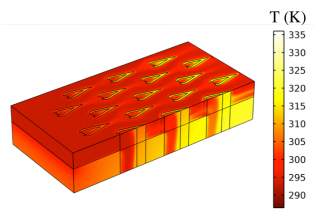

Microchannel has shown potential to dissipate high heat flux in past years [1][2]. At the same time, liquid cooling attracts more and more attention from researchers for its favorable thermal properties and ability to cool down hot and keep acceptable system temperature [3][4][5]. This work aims at modeling single-phase and two-phase flow boiling heat transfer and fluid flow with COMSOL Multiphysics® software in silicon microchannel. Furthermore, to enhance the heat transfer between hot surface and working fluid, a novel pin fin design piranha pin fin (PPF) is proposed as shown in Figure 1. For 3D single-phase modeling, conjugate heat transfer physics in COMSOL including laminar flow and heat transfer in liquid and solid is applied for single-phase flow. To optimize the design and operation of this microchannel heat exchanger, various flow conditions, working fluid and PPF’s configuration parameters are further studied. In terms of meshing, swept meshing method is utilized and a distribution is made in working fluid domain to obtain detailed information around boundary layers as shown in Figure 2. 3D symmetric geometry is applied based on the computation ability. HFE7000 is the working fluid. And study on other working fluid such as working is ongoing. Figure 3 shows temperature distribution for single-phase modeling.

For 2D two-phase flow, physics including laminar two-phase flow, phase field, heat transfer in fluids and laminar flow are applied. The idea of putting PPF in microchannel aims at extracting bubbles away from microchannel. In this way, the latent heat of working fluid is utilized to dissipate heat, at the same time; fewer vapors are left in microchannel. The fewer vapor in the channel, the less chance to reach critical heat flux (CHF). Based on computation ability, two pin fins with half of the geometry are studied. Figure 4 shows volume fraction of vapor in microchannel. It provides information for bubble dynamics and it is also a valuable start point for further exploration in 3-D two-phase modeling.

In conclusion, single-phase thermal performance of this microchannel with PPF can be evaluated by COMSOL single-phase modeling. At the same time, based on data from different PPF configurations, this microchannel design with PPF could be further optimized. Furthermore, 2D two-phase modeling in microchannel has been realized in microchannel with PPF, which will benefit the design of PPF with flow boiling regime in the future.

Herunterladen

- yu_presentation.pdf - 2.01MB

- yu_poster.pdf - 2.48MB

- yu_paper.pdf - 3.86MB

- yu_abstract.pdf - 1.5MB