Thermo-Fluid-Metallurgical Modeling and Parametric Study of Laser-Based Powder Bed Fusion Process

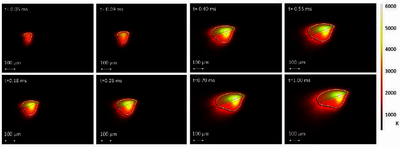

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal particles. Since the process is relatively fast and occurs at micron sizes, it would be very difficult to study the thermal and flow behavior of the material using online monitoring systems. Hence, to investigate the thermal and flow behavior of the material, a thermo-fluid dynamical model of the LPBF process has been developed in COMSOL Multiphysics® (Conjugate Heat Transfer, Laminar Flow interface is used) . For better accuracy of the results, temperature-dependent-volume-averaged material properties have been implemented. The model also takes into account both one-way and two-way transitions (powder to solid transition and melting respectively). To study the effect of the solidification on the metal fluid flow, volume forces are used (based on Carman-Kozeny equation), which are dependent on the solid volume fraction. These volume forces act as flow dampers and freeze the fluid flow where the material solidifies. Additionally, the thermo-capillary (Marangoni effect) force is included, where the planar temperature gradients cause the formation of shear stresses and later flow of the liquid metal. Furthermore, to study the metallurgical behavior of the material, a solidification sub-model has been developed in MATLAB® and coupled to the thermo-fluid solver via LiveLink™ for MATLAB®. Through this sub-model, important solidification parameters such as solidification thermal gradient, cooling rates, solidification velocity, solidification time, etc. are calculated on the solid/liquid interface during the solidification. In this work, the effect of the three main LPBF process parameters, namely the laser power, scanning speed and beam radius, on the size of the melt pool, material flow behavior and its crystal morphology has been investigated in full detail.

Herunterladen

- bayat_poster.pdf - 0.82MB

- bayat_paper.pdf - 0.76MB

- bayat_abstract.pdf - 0.02MB