Through Metal Communication for Using in Downhole Tool

For a specific project in downhole tools for oil and gas wells, we have to weld the tool before shipping and the tool must be programmed during installation on the rig location.

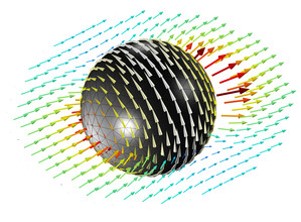

For this reason we decided to use magnetic communication and power transmission as well. We have used COMSOL Multiphysics®

a lot for feasible study of the concept, selecting the correct and commercial material for the body of the tool, finding optimum dimension of the coils and frequency responses for two way communication.

In this project we also needed to send some signals from inside the tool to outside programming device. The problem was we didn't have enough power to do it inside the tool because we only had 4 coin cell batteries. Also we couldn't listen to outside device for a long time (like one month) and it is possible that the time between welding the tool and programming it to be installed in the well be more than 6 months.

We used AC/DC module and some help from COMSOL support, finally we ran our model and found the optimum frequency for the power transmission (by considering the thermal loss and maximum safe voltage that we wanted to use on the rig)

Herunterladen

- Inductive_Communication_COMSOL.pptx - 3.37MB

- InductiveCommuniaction.pdf - 0.65MB