Sehen Sie, wie die Multiphysik-Simulation in verschiedenen Branchen eingesetzt wird

Multiphysik-Modellierung und -Simulation treiben Innovationen in Industrie und Wissenschaft voran – wie die zahlreichen Anwendungsbeispiele zeigen, die jedes Jahr in den Fachbeiträgen und Postern von Ingenieuren, Forschern und Wissenschaftlern auf der COMSOL Conference vorgestellt werden. Lassen Sie sich von den unten aufgeführten aktuellen Beiträgen inspirieren oder nutzen Sie die Schnellsuche, um eine bestimmte Präsentation zu finden oder nach Anwendungsbereich oder Konferenzjahr/-ort zu filtern.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

While copper remains the dominant material for conduction paths in printed circuit board (PCB) applications, both technological and economic reasons have been motivating research on substituting copper with aluminum (Al). Despite its 60 % higher specific electrical resistance, aluminum ... Mehr lesen

In this study, we attempted to develop a simulation to better understand the kinetic of the dye regeneration process in photoanodes of dye-sensitized solar cells (DSSCs). For that purpose, a numerical model was developed using finite element simulation in COMSOL Multiphysics®. The ... Mehr lesen

Structural Supercapacitors (SSC) are an important group of Multifunctional Energy Storage Composites (MESC) and can potentially play a significant role in lightweight design of aerospace and automotive applications [1]. Therefore, it is important to build accurate models based on the ... Mehr lesen

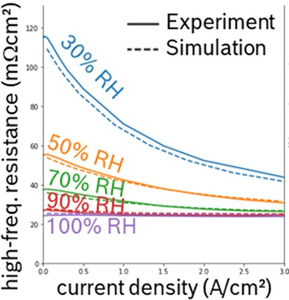

Proton exchange membrane fuel cells (PEMFCs) are promising energy converters, offering both sustainability and efficiency. Achieving optimal performance, however, requires a deep understanding of the underlying cause-effect relationships within the functional layers. One effective ... Mehr lesen

In the construction sector, the concrete and the steel bars represent still the key components, although they are very vulnerable by the atmospheric agents, as in the case of their degradation caused by corrosion. The value of the concrete carbonation may enhance the corrosion around the ... Mehr lesen

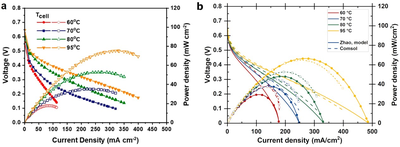

Ammonia is studied both as a hydrogen carrier and as a fuel for renewable energy infrastructure. An important advantage of ammonia compared to carbon-based fuels is that it can be oxidized without greenhouse gas emissions, producing only N2 and water. Direct ammonia fuel cells (DAFCs) ... Mehr lesen

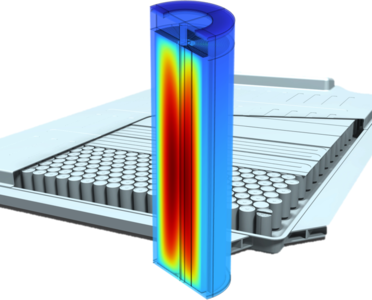

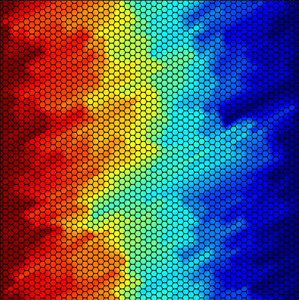

The accurate modeling and simulation of battery cells are crucial for the optimization and design of efficient energy storage systems. The choice of an appropriate battery simulation model heavily depends on the specific problem being investigated. This poster presents a comparative ... Mehr lesen

With the ongoing electrification of vehicles as well as rapid digitalization, thermal management is on everyone´s lips. This includes the use of ever-better materials, specifically tailored regarding their thermal properties. To fine-tune the thermal conductivity of a material, composite ... Mehr lesen

Fuel cells are considered one of the most promising alternatives to conventional energy sources due to their high energy efficiency and only water from the exhaust. Accurate modeling of the fuel cell electrochemistry is crucial to optimize fuel cell performance. In this study, we ... Mehr lesen

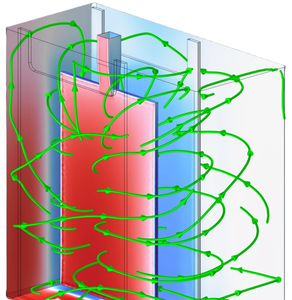

The Water management is a central issue in proton exchange membrane (PEM) Fuel Cell. The polymer electrolyte membrane required sufficient water to exhibit a high ionic conductivity. The water molecules in fuel cell operation, moves through the membrane under electro-osmotic drag, ... Mehr lesen