Sehen Sie, wie die Multiphysik-Simulation in verschiedenen Branchen eingesetzt wird

Multiphysik-Modellierung und -Simulation treiben Innovationen in Industrie und Wissenschaft voran – wie die zahlreichen Anwendungsbeispiele zeigen, die jedes Jahr in den Fachbeiträgen und Postern von Ingenieuren, Forschern und Wissenschaftlern auf der COMSOL Conference vorgestellt werden. Lassen Sie sich von den unten aufgeführten aktuellen Beiträgen inspirieren oder nutzen Sie die Schnellsuche, um eine bestimmte Präsentation zu finden oder nach Anwendungsbereich oder Konferenzjahr/-ort zu filtern.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

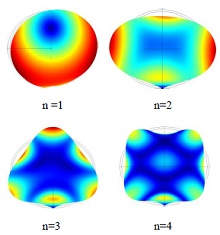

In this paper, a Finite Element (FE) and scaled-up experimental modal analysis are employed to estimate the natural frequencies of individual spherical and ellipsoidal cells. It is apparent that the mechanical properties of the living cells and particularly the natural frequencies might ... Mehr lesen

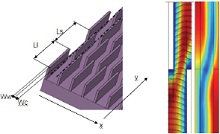

Convective deposition is a material processing technique where an evaporating meniscus of a colloidal suspension is dragged along a solid substrate to deposit layers of micro or nanoparticles. The process is a typical multiphysics process where fluid dynamics, mass and heat transfer come ... Mehr lesen

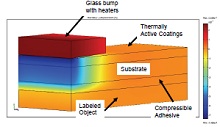

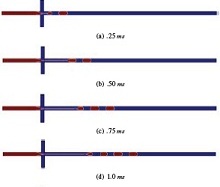

In direct thermal printing, media is exposed to heat pulses from a print head carrying a linear array of resistive heaters. In this study we investigate the degree to which a thin substrate can be combined with a more compressible sub-layer to provide a composite structure that will hug ... Mehr lesen

An interaction of aluminum aircraft skins with a laboratory-simulated, low-level, long-duration, continuing current representative of a natural lightning flash was modeled with COMSOL Multiphysics. For the analysis of the lightning direct effects on aircraft, the external environment is ... Mehr lesen

Self-propagating High-temperature Synthesis (SHS), a very economical synthesis of oxides was used in our lab to produce oxide materials. SHS process uses a highly exothermic reaction to convert reactants rapidly to pure products with minimal external energy input. This reaction is ... Mehr lesen

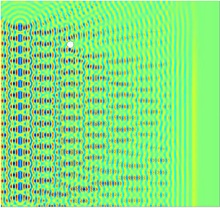

Acoustic Imaging of hand movement is being studied with COMSOL and Matlab. A hardware implementation is being pursued that will be an array of 16x16 ultra-sonic speakers placed in a grid facing a similar grid of 16x16 microphones, operating at 40kHz. COMSOL is used to repeatedly ... Mehr lesen

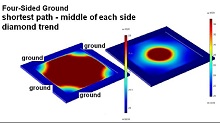

For this work the multi-objective design environment modeFRONTIER was integrated with COMSOL, bringing the advantages of multi-objective optimization to multiphysics simulations. Practically any commercial analysis tool (such as COMSOL) or in-house code can be integrated within ... Mehr lesen

NASA and the Department of Defense have interest in the development of satellites which are several orders of magnitude smaller than those currently in use. These ‘nanosats’ will require new propulsion systems to offer precise thrust and impulse-bit characteristics on the order of 10 ... Mehr lesen

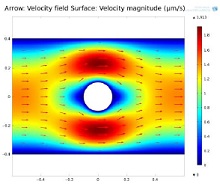

Particle velocimetry using image analysis is an effective non-intrusive method used for fluid velocity field estimation in micro-channels. We use COMSOL with MATLAB to generate velocity fields for micro-channel designs and then calculate changes in particle position for given imaging ... Mehr lesen

Efficient modeling and computation of the nonlinear interaction of fluid with a solid undergoing nonlinear deformation has remained a challenging problem in computational science and engineering. Direct numerical simulation of the non-linear equations, governing even the most simplified ... Mehr lesen