Sehen Sie, wie die Multiphysik-Simulation in verschiedenen Branchen eingesetzt wird

Multiphysik-Modellierung und -Simulation treiben Innovationen in Industrie und Wissenschaft voran – wie die zahlreichen Anwendungsbeispiele zeigen, die jedes Jahr in den Fachbeiträgen und Postern von Ingenieuren, Forschern und Wissenschaftlern auf der COMSOL Conference vorgestellt werden. Lassen Sie sich von den unten aufgeführten aktuellen Beiträgen inspirieren oder nutzen Sie die Schnellsuche, um eine bestimmte Präsentation zu finden oder nach Anwendungsbereich oder Konferenzjahr/-ort zu filtern.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

Deformation prediction is an important part of the structure stability analysis. However, the deformation of bank protection structure which is affected by many factors, such as structural stiffness, earth pressure and hydrostatic pressure. It contains a complex mechanical process, which ... Mehr lesen

Machines with rotating components are prone to vibrations because an imbalance of the rotor would always act as a harmonic excitation force to the machine. Thus oscillations close to the natural frequencies are tried to pass through fast in the run-up and cast-down or even completely ... Mehr lesen

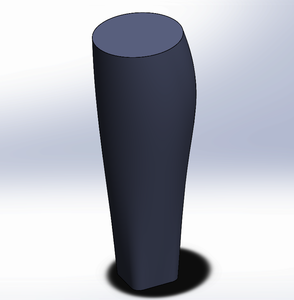

The evolution of specific three dimensional (3D) fabrication printing technologies has developed the capability to fabricate functional parts in several fields of engineering. This has also enabled the possibility to create optimized complex organic structures to use, for example, in new ... Mehr lesen

As a sustainable urban transport system, the tricycle can represent an adaptive mobility vehicle used to transport people and bulk load. This transport system must guarantee the security of its end users, so experimental and modeling works are very useful tools in order to evaluate the ... Mehr lesen

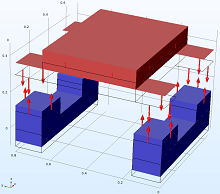

Current trends of research aims at the reduction of conventional fossil fuel consumption so as to mitigate anthropogenic global warming and thus to combat with the climate change. This can be done by shifting to more efficient, alternate, non-conventional and environmental friendly ... Mehr lesen

Mechanics of living cells and tissues play a central role in many phenomena, from tissue shape formation (morphogenesis) to migration of cells within tissues. One prominent example is the epithelia – a sheet of cells tightly attached to one another. It provides a physical barrier to ... Mehr lesen

In general this thesis is about the effects of mechanical stress on data cables in moved applications. If a data cable is loaded with different kind of forces and used within high frequency applications it is possible, that the geometrical changes may have an impact on the electrical ... Mehr lesen

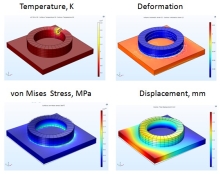

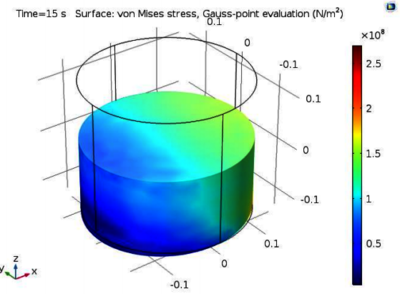

The results of modeling of thermal fields, stresses, deformations and displacements in formation of an additive structure from structural low alloy steel for welding 09G2S on a substrate are presented. An interdisciplinary research computational package COMSOL Multiphysics® was used for ... Mehr lesen

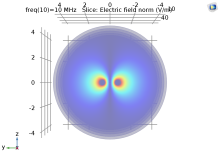

Power cable manufacturing is limited by the maximum length of cable that can be produced and stored on cable drums. This creates a need or rather an opportunity for a cable accessory, namely 'Cable Joints'. Joints are an impeccable component in the power cable network that necessitate ... Mehr lesen

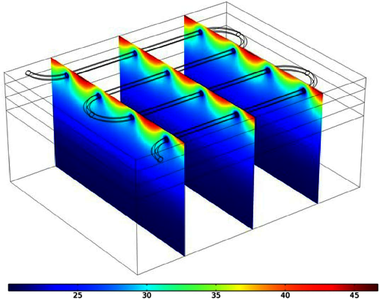

A very important phase in construction of a pavement structure is the compaction process of the asphaltic mixture. It reflects a complex mechanism where many parameters are influential. These parameters are associated with the initial air voids content in the asphaltic mixture, aggregate ... Mehr lesen