Optimizing 3D Printing Techniques with Simulation Apps

Borja Lazaro Toralles, MTC, Coventry, UK3D printing has recently revolutionized manufacturing techniques, influencing countless industries and products. The Manufacturing Technology Centre (MTC), in Coventry, UK, is optimizing the 3D metal printing technique called shaped metal deposition (SMD) for industrial use. Unlike common additive manufacturing technologies, with SMD, a thin layer of molten metal is deposited layer by layer on a surface, allowing for use of multiple materials on one part. However, due to the intense heat of the metal, the final piece can deform during printing.

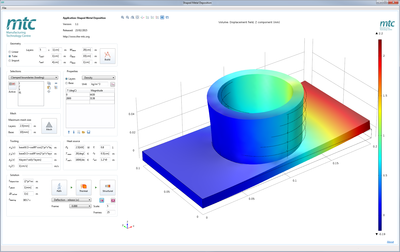

The MTC engineers use simulation apps built with the Application Builder available in COMSOL Multiphysics to predict the geometry of the final part prior to its production. Team members without simulation experience and the MTC engineers can use the app to explore different parts and test designs to determine the optimal deposition process for a desired part. These apps will help make the technology ready for use on the industrial market.

Shaped metal deposition (SMD) simulation app created using the Application Builder available in COMSOL Multiphysics.

Shaped metal deposition (SMD) simulation app created using the Application Builder available in COMSOL Multiphysics.

Herunterladen

- MTC_CN2015.pdf - 1.05MB