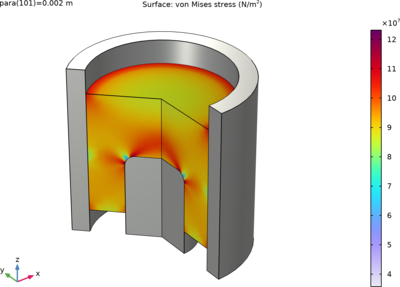

Powder Compaction of a Cup

Application ID: 46931

The fabrication of a cup through powder compaction is simulated in this tutorial model. The powder compaction process is becoming common in the manufacturing industry, due to its potential for producing components of complex shape and high strength.

Combining the Fleck–Kuhn–McMeeking (FKM) model with the Gurson–Tvergaard–Needleman (GTN) model for porous plasticity makes it possible to cover a wide range of porosity values. This example uses that technique and takes into account the friction between metal powder and die.

The highly nonlinear structural analysis is performed by considering the contact interaction between the moving parts, the elastoplastic constitutive law selected for the metal powder, and the geometrical nonlinearity caused by the large displacements.

You can find out more about this tutorial model in the blog post "Simulating Powder Compaction with Porous Plasticity Models".

Dieses Beispiel veranschaulicht Anwendungen diesen Typs, die mit den folgenden Produkten erstellt wurden:

Allerdings können zusätzliche Produkte erforderlich sein, um es vollständig zu definieren und zu modellieren. Weiterhin kann dieses Beispiel auch mit Komponenten aus den folgenden Produktkombinationen definiert und modelliert werden:

- COMSOL Multiphysics® und

- Nonlinear Structural Materials Module und

- entweder MEMS Module, oder Structural Mechanics Module

Die Kombination von COMSOL® Produkten, die für die Modellierung Ihrer Anwendung erforderlich ist, hängt von verschiedenen Faktoren ab und kann Randbedingungen, Materialeigenschaften, Physik-Interfaces und Bauteilbibliotheken umfassen. Bestimmte Funktionen können von mehreren Produkten gemeinsam genutzt werden. Um die richtige Produktkombination für Ihre Modellierungsanforderungen zu ermitteln, lesen Sie die Spezifikationstabelle und nutzen Sie eine kostenlose Evaluierungslizenz. Die COMSOL Vertriebs- und Support-Teams stehen Ihnen für alle Fragen zur Verfügung, die Sie diesbezüglich haben.