Die Application Gallery bietet COMSOL Multiphysics® Tutorial- und Demo-App-Dateien, die für die Bereiche Elektromagnetik, Strukturmechanik, Akustik, Strömung, Wärmetransport und Chemie relevant sind. Sie können diese Beispiele als Ausgangspunkt für Ihre eigene Simulationsarbeit verwenden, indem Sie das Tutorial-Modell oder die Demo-App-Datei und die dazugehörigen Anleitungen herunterladen.

Suchen Sie über die Schnellsuche nach Tutorials und Apps, die für Ihr Fachgebiet relevant sind. Beachten Sie, dass viele der hier vorgestellten Beispiele auch über die Application Libraries zugänglich sind, die in die COMSOL Multiphysics® Software integriert und über das Menü File verfügbar sind.

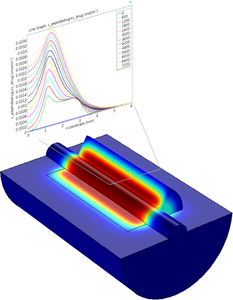

In diesem Beispiel wird die Freisetzung eines Medikaments aus einer Biomaterialmatrix in beschädigtes Zellgewebe modelliert. Konkret liefert eine Nervenleitschiene ein regenerierendes Medikament an geschädigte Nervenenden. Das Modell beinhaltet eine detaillierte Kinetik der ... Mehr lesen

Chemical vapor deposition (CVD) allows a thin film to be grown on a substrate through molecules and molecular fragments adsorbing and reacting on a surface. This example illustrates the modeling of such a CVD reactor where triethyl-gallium first decomposes, and the reaction products ... Mehr lesen

In this application, a solution is pumped through a catalytic bed where a solute species reacts as it gets in contact with the catalyst. The purpose of this example is to maximize the total reaction rate for a given total pressure difference across the bed by finding an optimal catalyst ... Mehr lesen

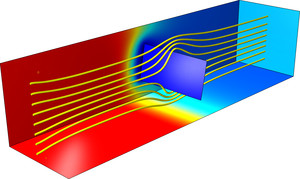

In static mixers, also called motionless or in-line mixers, a fluid is pumped through a pipe containing stationary blades. This mixing technique is particularly well suited for laminar flow mixing because it generates only small pressure losses in this flow regime. This example studies ... Mehr lesen

Silicon carbide (SiC) epitaxial furnaces are a specialized equipment for the production and preparation of SiC epitaxial wafers. This example model demonstrates the process of preparing an SiC epitaxial wafer based on the physical vapor transport (PVT) method in a furnace. This involves ... Mehr lesen

Maximizing product yield is a main task in chemical reaction engineering. This can be especially challenging if the desired product, once formed, can be consumed by further reactions. This example investigates such a series reaction as it occurs in a tubular reactor. You will start by ... Mehr lesen

The pyrolysis of a centimeter-sized wood particle presents a fully coupled multiphysics problem with mass transfer, fluid flow, and heat transfer. This example model consists of two parts. The first part demonstrates how to set up a model describing the pyrolysis of a porous, ... Mehr lesen

Removing halogen groups from hydrocarbons is an important reaction step in several chemical processes. One application is water purification. Other examples involve organic synthesis, where the removal of halogen groups serves as a starting point for carbon-carbon coupling reactions. ... Mehr lesen

Tubular reactors are often used in continuous large-scale production, for example in the petroleum industry. One key design parameter is the conversion, or the amount of reactant that reacts to form the desired product. In order to achieve high conversion, process engineers optimize the ... Mehr lesen

An important step in brewing beer is the fermentation process. Here, alcohol is formed together with various flavor substances from sugars in the presence of yeast. The initial sugar content, temperature, and yeast type dictate how the fermentation proceeds. In this example, the ... Mehr lesen