Sehen Sie, wie die Multiphysik-Simulation in verschiedenen Branchen eingesetzt wird

Multiphysik-Modellierung und -Simulation treiben Innovationen in Industrie und Wissenschaft voran – wie die zahlreichen Anwendungsbeispiele zeigen, die jedes Jahr in den Fachbeiträgen und Postern von Ingenieuren, Forschern und Wissenschaftlern auf der COMSOL Conference vorgestellt werden. Lassen Sie sich von den unten aufgeführten aktuellen Beiträgen inspirieren oder nutzen Sie die Schnellsuche, um eine bestimmte Präsentation zu finden oder nach Anwendungsbereich oder Konferenzjahr/-ort zu filtern.

Sehen Sie sich die Kollektion für die COMSOL Conference 2024 an

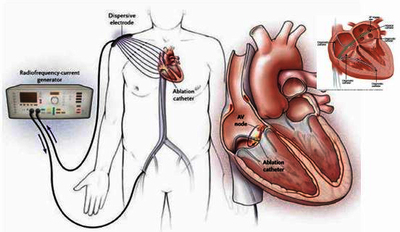

Radiofrequency (RF) ablation is a treatment modality that kills unwanted tissue by heat. RF ablation is now the treatment of choice for certain types of cardiac arrhythmia. During RF ablation, an electrode is inserted into, or steered intravascularly to the target tissue region under ... Mehr lesen

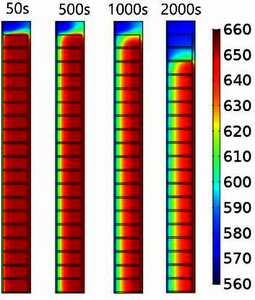

Magnesium hydride (MgH2) has been one of the most promising hydrogen storage methods that can be applied to commercial hydrogen energy systems due to magnesium’s safety, low cost, and excellent storage capacity for hydrogen, compared to other reversible metal hydrides. But hydrogen ... Mehr lesen

Extensive research efforts have been dedicated recently to developing and characterizing metamaterials that improve the performance of common thermoelectric materials and the electric contacts within a thermoelectric generator (TEG). With increasing demand for clean energy and climate ... Mehr lesen

The emerging technologies related to AI and Quantum Computing are shifting the nano-bio-info paradigm, reconsidering the presently assumed bioenergetic processes of the living cells. Thus, a key process as ATPase can be considered through a model governed by quantum field theory (QFT) ... Mehr lesen

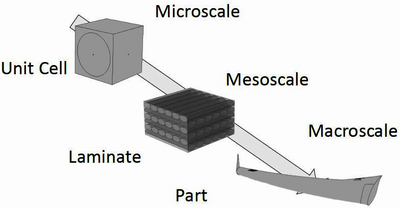

Fiber-reinforced composite materials are widely used for building lightweight parts in several application fields like aviation or naval industry. Here the longitudinal fibers, which take the main mechanical loads of the component, are embedded in a shape giving resinous matrix. The ... Mehr lesen

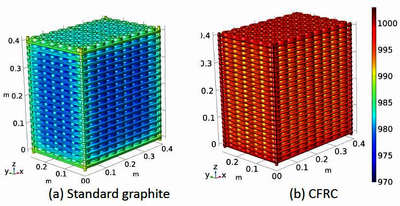

The advantages of carbon based materials at high temperature applications are their lightweight high-temperature stability, chemical resistance combined with good thermally and electrically conducting properties. In such applications, typically materials like graphite and carbon fiber ... Mehr lesen

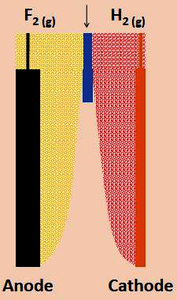

Gaseous fluorine plays a major role in the nuclear industry since it is used to produce uranium hexafluoride, whose physical properties are the key to classical uranium enrichment processes. The fluorine production process is based on the electrolysis of an anhydrous HF-composed molten ... Mehr lesen

Hyperloop is a future concept of mass transportation proposed by Elon Musk. It uses electromagnetic propulsion to accelerate a passenger or cargo pod through a low-pressure tube. HYPED, the University of Edinburgh’s Hyperloop Team has created a prototype that uses linear halbach arrays ... Mehr lesen

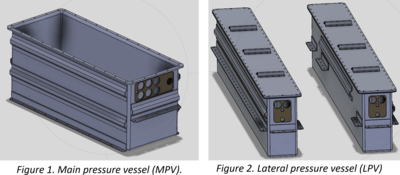

The Hyperloop is a concept system targeting passenger transportation aiming to carry people in a pod running in a high vacuum tube at 1200 km/h. In 2015, SpaceX announced that they would sponsor a Hyperloop pod design competition, because of their interest in helping to accelerate the ... Mehr lesen

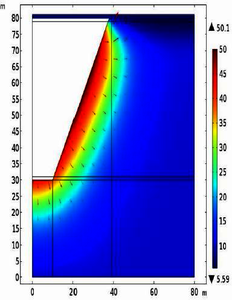

Seasonal thermal energy storage (STES) systems are key components for expanding the renewables share in the energy scheme as they offer the dispatchability and flexibility. Therefore, thermal behaviour of such systems is of interest. STES can influence the surroundings causing a ... Mehr lesen