Gezeigt werden Events mit Startzeiten zwischen: 08:00 – 20:00

Suchen

Bevorstehende Events

Lade Events

März 3–6

| 11:00 EST

Introduction to COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

März 10

| 09:00 CET

GPU Acceleration in COMSOL®

COMSOL

Webinar

Online

März 10

| 10:00 GMT

Time-Optimal Control with COMSOL Multiphysics® in 18 Minutes

COMSOL

Webinar

Online

März 10–13

| 11:00 EDT

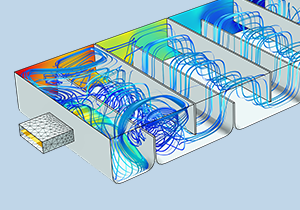

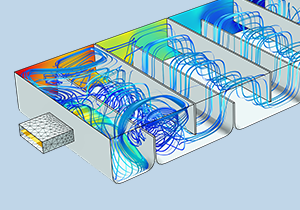

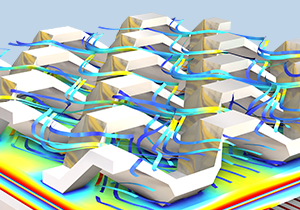

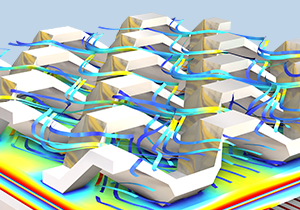

CFD Modeling in COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

März 12

| 14:00 EDT

Phased-Array Antenna Modeling: Techniques to Optimize RF Design

Machine/Electronic Design

Webinar

Online

März 15–19

| 10:00 CDT

AMPP

COMSOL

Exhibition

Houston

März 17–19

| 09:00 EDT

Optical Fiber Communications Exhibition

COMSOL

Exhibition

Los Angeles

März 17

| 09:00 CET

CFD Modeling with COMSOL® in 18 Minutes

COMSOL

Webinar

Online

März 17

| 11:00 EDT

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics®

COMSOL

Webinar

Online

März 19

| 14:00 EDT

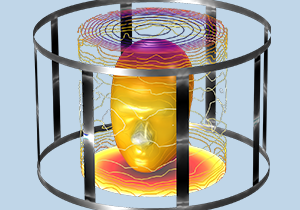

Exploring Light and Life: Nanophotonics and AI for Molecular Sequencing and Single-Cell Phenotyping

IEEE

Webinar

Online

März 23–26

| 09:00 EDT

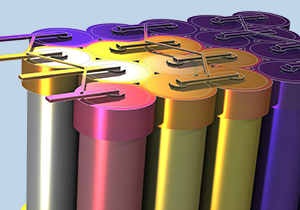

International Battery Seminar

COMSOL

Exhibition

Orlando

März 24–27

| 11:00 EDT

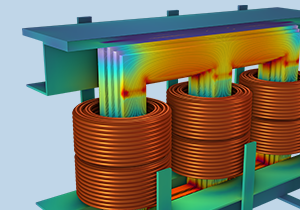

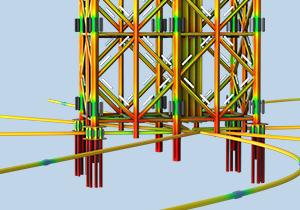

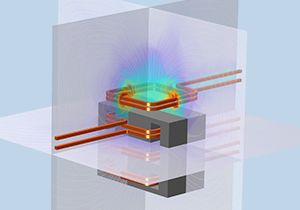

AC/DC Modeling in COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

März 25

| 10:00 GMT

Solving Large Models in COMSOL Multiphysics®

COMSOL

Webinar

Online

März 26

| 11:00 EDT

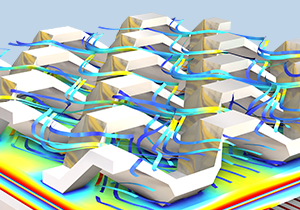

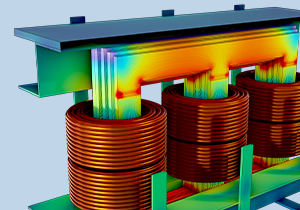

COMSOL Day: Electric Power

COMSOL

COMSOL Day

Online

März 26

| 11:00 EDT

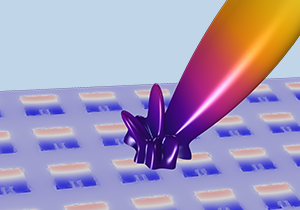

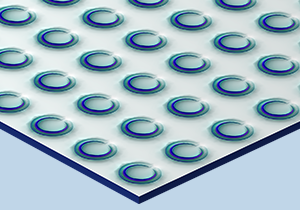

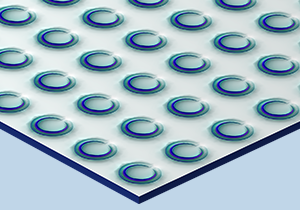

Photo-Thermo-Optical Effects in Metasurfaces: From Optical to Thermochemical Devices

Photonics Spectra

Webinar

Online

Apr. 14

| 08:00 CEST

Modeling Granular Flow in COMSOL®

COMSOL

Webinar

Online

Apr. 14

| 11:00 EDT

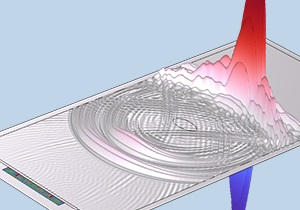

Multiphysics Modeling for Acoustics Applications, Part 1: Acoustic–Structure Interaction (Vibroacoustics)

COMSOL

Webinar

Online

Apr. 14–17

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

Apr. 21

| 08:00 CEST

Simulation Apps & Digital Twins for the Renewable Energy Industry

COMSOL

Webinar

Online

Apr. 21–24

| 11:00 EDT

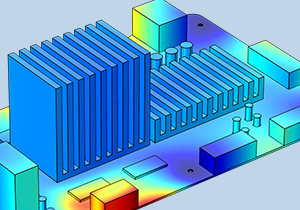

Heat Transfer Modeling in COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

Apr. 28–29

| 09:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Trainingskurs

Burlington

Apr. 30

| 09:00 BST

Modeling Biochemical Sensors and Testing Devices with COMSOL®

COMSOL

Webinar

Online

Mai 5

| 11:00 EDT

Multiphysics Modeling for Acoustics Applications, Part 2: Acoustic-Thermal Interaction (Thermoacoustics)

COMSOL

Webinar

Online

Mai 5–8

| 11:00 EDT

Acoustics Modeling in COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

Mai 8

| 12:00 PDT

COMSOL Simulation Summit: Santa Clara

COMSOL

Summit

Santa Clara

Mai 12

| 08:00 CEST

Equation-Based Modeling with COMSOL®

COMSOL

Webinar

Online

Mai 19

| 08:00 CEST

Preparing CAD for Analysis with COMSOL®

COMSOL

Webinar

Online

Mai 19–22

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

Mai 26

| 11:00 EDT

Multiphysics Modeling for Acoustics Applications, Part 3: Acoustic-Flow Interaction (Aeroacoustics)

COMSOL

Webinar

Online

Juni 9

| 08:00 CEST

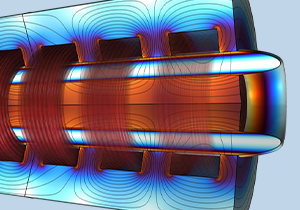

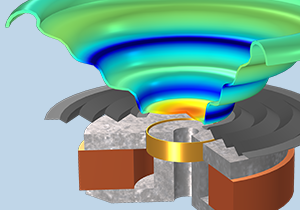

Modeling Electric Motors & Generators

COMSOL

Webinar

Online

Juni 23

| 08:00 CEST

CFD Modeling with COMSOL® in 18 Minutes

COMSOL

Webinar

Online

Juni 23–26

| 11:00 EDT

Introduction to COMSOL Multiphysics®

COMSOL

Trainingskurs

Online

8 von 32 Events werden angezeigt

32 von 32 Events werden angezeigt

Trainings durch Certified Consultants

Aufgezeichnete Webinare

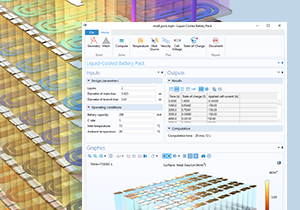

Why Model and Simulate Batteries?

Webinar

Mar 04

Editing, Repairing, and Combining Imported STL Files with CAD

Webinar

Mar 03

Modeling Rotordynamics with COMSOL Multiphysics®

Webinar

Feb 26

The Basics of COMSOL® in 18 Minutes

Webinar

Feb 26

Modeling Nonlinear Photonics in Dielectric Resonant Metasurfaces Using COMSOL®

Webinar

Feb 18

Modeling and Simulation of MEMS Devices

Webinar

Feb 04

Modeling Photonic Crystals in COMSOL Multiphysics

Webinar

Jan 29

Modeling Emerging Battery Technologies with COMSOL Multiphysics®

Webinar

Jan 28

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Jan 27

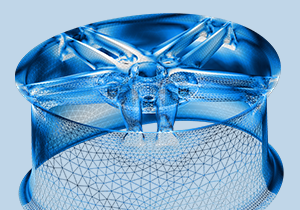

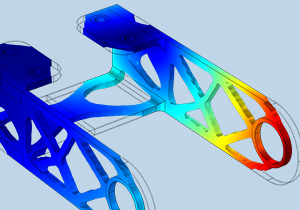

Shape and Topology Optimization with COMSOL Multiphysics®

Webinar

Jan 22

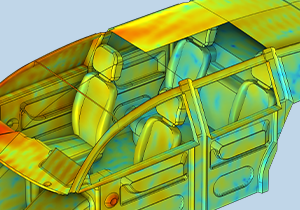

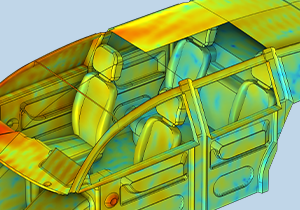

Automotive Acoustics Analysis Using COMSOL Multiphysics

Webinar

Jan 21

Polymer Flow Modeling

Webinar

Jan 13

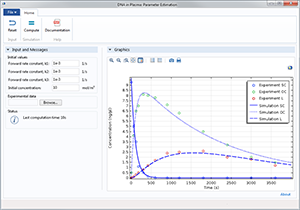

Parameter Estimation for Nonlinear Materials

Webinar

Dec 11

Introducing COMSOL Multiphysics® Version 6.4

Webinar

Dec 10

Multiphysics Simulation of Power Transformers

Webinar

Dec 09

Multiphysics Simulation for Vehicle Electrification

Webinar

Dec 02

Optimising Manufacturing Processes Through Simulation

Webinar

Nov 26

Designing Efficient Electric Motors with COMSOL Multiphysics

Webinar

Nov 26

Efficient Battery Modeling with Surrogate Models

Webinar

Nov 19

Automating Your Modeling Workflow in COMSOL Multiphysics®

Webinar

Nov 18

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Nov 11

Modeling Pipe Flow & Heat in COMSOL Multiphysics®

Webinar

Nov 06

Modeling Gyroscopes and Accelerometers in COMSOL Multiphysics®

Webinar

Oct 30

Modeling and Simulation for Electric Motor Design

Webinar

Oct 15

Simulating Electrical Power Systems for the Grid

Webinar

Oct 14

Unravelling Chemomechanical Effects in Lithium-Ion Batteries

Webinar

Oct 09

Optimierung keramischer 3D-Drucke durch Simulation

Webinar

Oct 09

Modeling Next-Generation Battery Technologies with COMSOL Multiphysics®

Webinar

Oct 06

Modeling Emerging Battery Technologies with COMSOL Multiphysics®

Webinar

Sep 25

Modeling and Simulation of MEMS Devices

Webinar

Sep 23

Elektrische Entladungen modellieren

Webinar

Sep 18

Modeling Reaction Kinetics and Pharmacokinetics with COMSOL Multiphysics®

Webinar

Sep 11

Modeling Ultrasound for Biomedical Applications

Webinar

Sep 09

Optimization of Thermal Management Systems

Webinar

Sep 03

Prediction of Electromagnetic Signatures of Naval Vessels with COMSOL Multiphysics

Webinar

Aug 28

Modeling Room Acoustics in COMSOL Multiphysics®

Webinar

Aug 19

Modeling and Simulation for Electric Motor Design

Webinar

Aug 14

Moisture Transport Modeling in COMSOL Multiphysics®

Webinar

Aug 07

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinar

Aug 06

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Aug 05

Modeling Acoustic Metamaterials in COMSOL Multiphysics

Webinar

Jul 31

Fatigue and Durability Analysis Using COMSOL Multiphysics®

Webinar

Jul 24

Biomedical Modeling with COMSOL Multiphysics

Webinar

Jul 17

Understanding Liquid Metal Transport in Magnetic Fields — Simulating Magnetohydrodynamic Duct Flow

Webinar

Jul 11

Modeling Electric Motors and Drivetrains

Webinar

Jul 10

Memristor Modeling with COMSOL Multiphysics®

Webinar

Jul 02

Modellierung optischer Nanostrukturen mit COMSOL Multiphysics®

Webinar

Jun 17

Underwater Acoustics

Webinar

Jun 12

Optimization in Structural Mechanics

Webinar

Jun 12

Hydrogen Technology Innovation with Simulation

Webinar

Jun 12

Modeling Hydrogen Fuel Cells and Electrolyzers

Webinar

Jun 12

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinar

Jun 05

Introduction to Multibody Dynamics Modeling with COMSOL Multiphysics

Webinar

May 28

Automotive Acoustics Analysis Using COMSOL Multiphysics®

Webinar

May 27

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinar

May 09

Demokratisierung der Multiphysik-Simulation

Webinar

May 08

The Basics of COMSOL Multiphysics® in 18 Minutes

Webinar

Apr 15

Wave & Ray Optics Modeling with COMSOL®

Webinar

Apr 09

Optimization in RF and Wave Optics

Webinar

Apr 09

Multiphysics Simulation in Semiconductor Packaging

Webinar

Apr 03

Acoustics in Electronics Webinar Series, Part 1: Loudspeakers

Webinar

Mar 25

Simulating Electrical Power Systems for the Grid

Webinar

Mar 20

Modellierung biomedizinischer Geräte mit COMSOL Multiphysics®

Webinar

Mar 20

Multiphysics Modeling of Electronic Components

Webinar

Mar 20

Improving Thermal Management of Batteries with COMSOL Multiphysics®

Webinar

Mar 18

Modeling Chemical Reactions and Reacting Flows Using COMSOL Multiphysics®

Webinar

Mar 06

6 von 66 Events werden angezeigt

66 von 66 Events werden angezeigt

- Produktinformationen

- Produkte

- Spezifikationstabelle

- Lizenzoptionen

- Systemanforderungen

- Release-Historie

- Support und Service

- Support Center

- Meine Supportfälle

- Knowledge Base

- Partner und Consultants

- Dokumentation

- Produkt Download

- Unternehmen

- Über COMSOL

- Karriere

- Presse

- Kontakt

- |

- Datenschutzerklärung

- |

- Warenzeichen

- |

- Cookie Settings

- © 2026 by COMSOL. Alle Rechte vorbehalten