Neuerungen im Metal Processing Module

Für Nutzer des Metal Processing Module bietet Version 6.4 ein neues Multiphysik-Interface für das Induktionshärten, neue Phasenübergangsmodelle für die Austenitisierung und Funktionen zur Modellierung spannungsabhängiger martensitischer Phasenübergänge. Mehr über diese Neuerungen erfahren Sie hier.

Multiphysik-Interface Induction Hardening

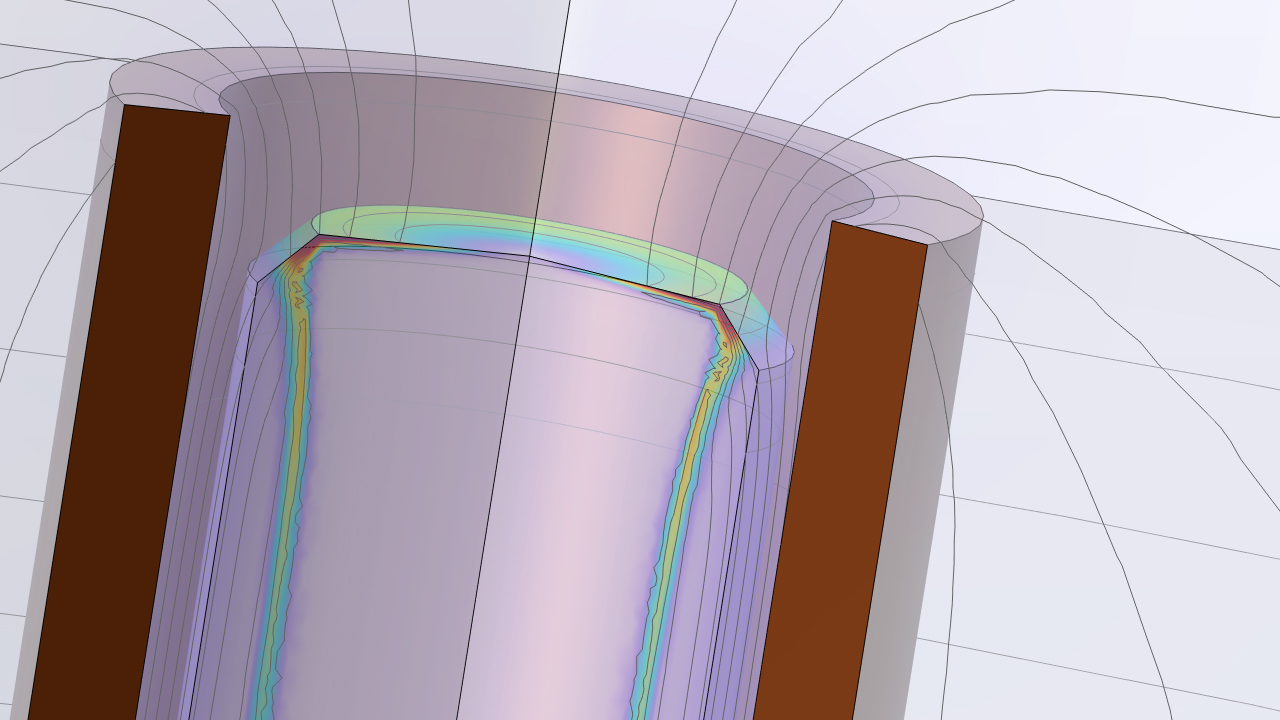

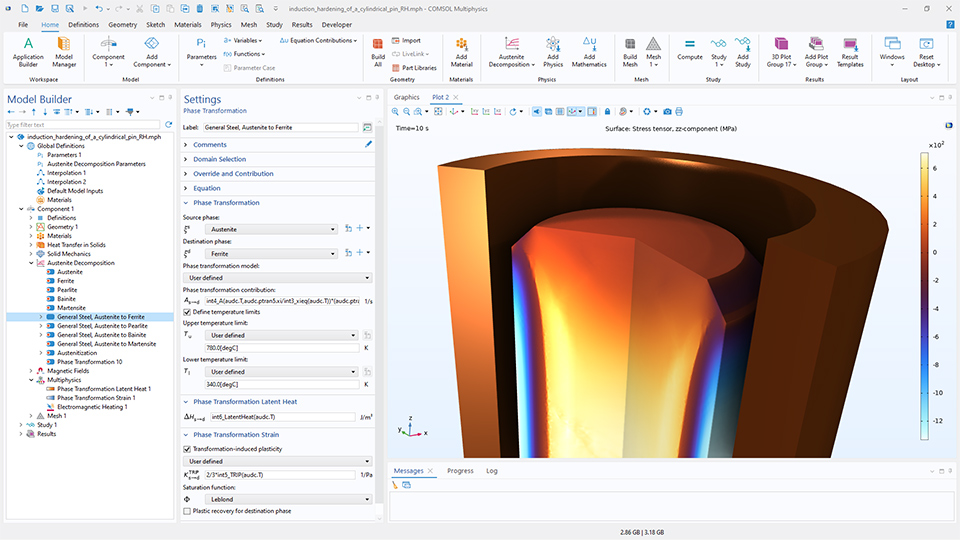

Zur Modellierung von Induktionshärtungsprozessen für Stahlteile steht ein neues Multiphysik-Interface Induction Hardening zur Verfügung. Dieses Feature umfasst die Modellierung der lokalisierten Induktionserwärmung mithilfe einer Spule und das anschließende Abschrecken des Stahlteils, um eine harte Oberfläche und einen weicheren Kern zu erzielen. Durch die Kopplung mit der Festkörpermechanik können Restspannungen, Dehnungen und Verformungen berechnet werden. Für dieses Interface ist außerdem das AC/DC Module erforderlich.

Phasenübergangsmodelle für die Austenitisierung

Zur Modellierung der Austenitisierung von Stahlphasen während des Erhitzens wurden zwei neue Phasenübergangsmodelle eingeführt: das Modell Linear und das Modell Oddy–McDill–Karlsson. Das Modell Linear bietet eine einfache Möglichkeit, die Bildung von Austenit zu beschreiben, und ist in Situationen nützlich, in denen keine vollständigen Details zur austenitischen Umwandlung der ferritischen Phasen erforderlich sind. Das Modell Oddy–McDill–Karlsson eignet sich für die Erwärmung von hypereutektoiden Stählen und wird zur Modellierung der Bildung einer eutektoiden Austenitfraktion verwendet. Das Tutorial-Modell Induction Hardening of a Cylindrical Pin verwendet das Modell Linear, um die Austenitisierung zu beschreiben.

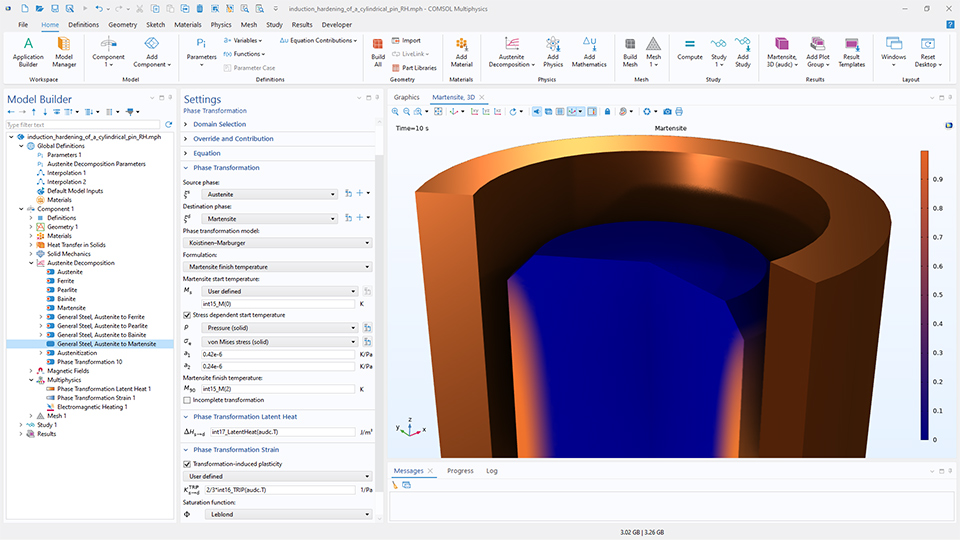

Spannungsabhängige martensitische Phasenübergänge

Der Beginn des martensitischen Übergangs kann durch eine von außen aufgebrachte Spannung beeinflusst werden. Es ist nun möglich, diese Spannungen durch eine Verschiebung der Martensitstarttemperatur Ms auf das Phasenübergangsmodell wirken zu lassen. Die Starttemperatur wird in Abhängigkeit vom Druck und der effektiven (Von-Mises-) Spannung verschoben.

Neues Tutorial-Modell

COMSOL Multiphysics® Version 6.4 enthält ein neues Tutorial-Modell für das Metal Processing Module.

Induction Hardening of a Cylindrical Pin

induction_hardening_of_a_cylindrical_pin

Download aus der Application Gallery