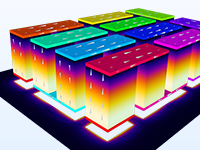

Formen des Wärmetransports

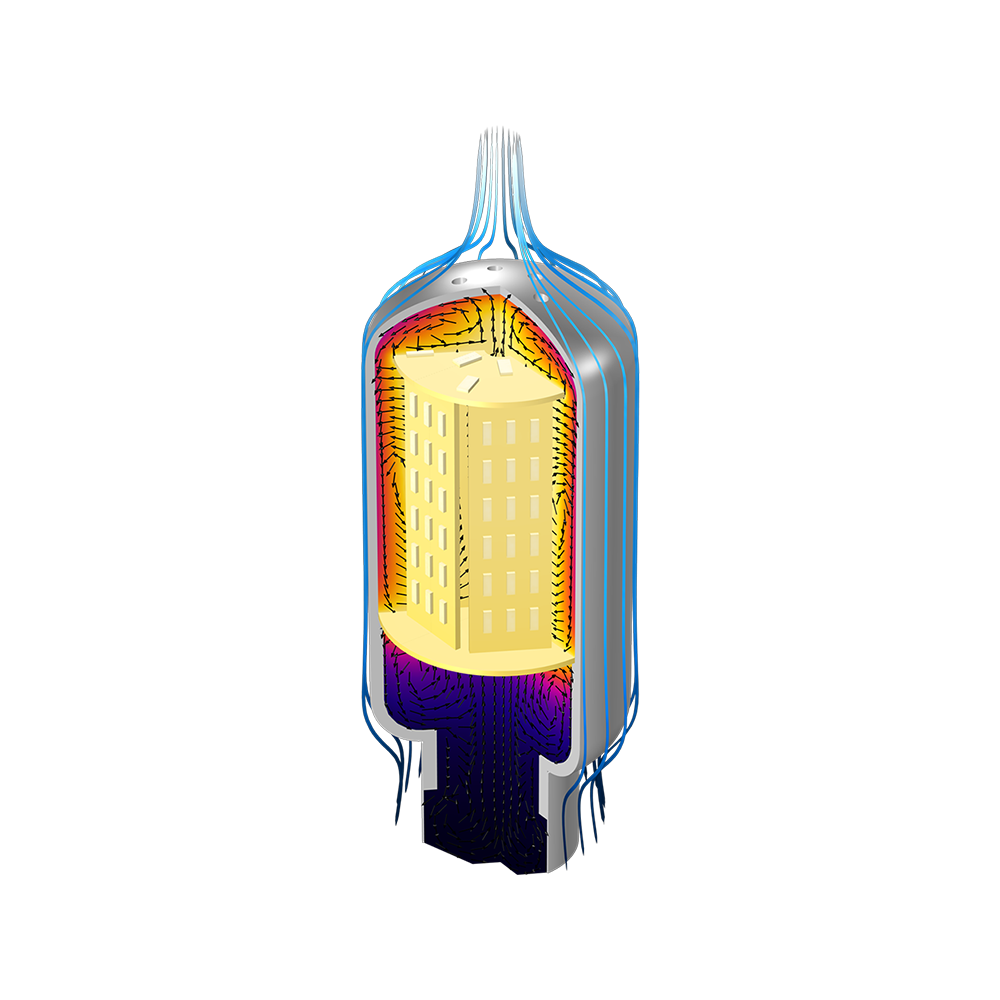

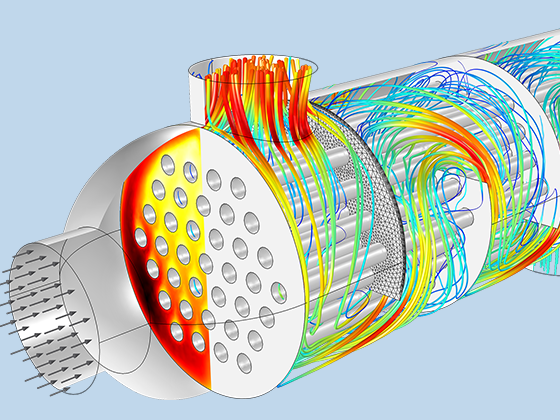

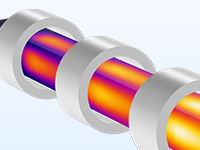

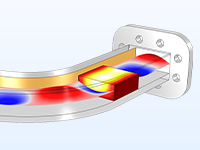

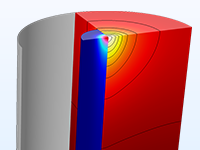

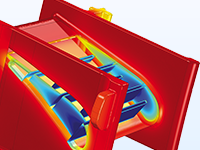

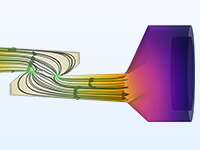

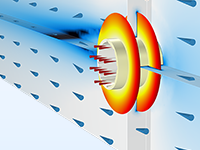

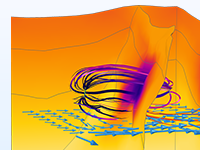

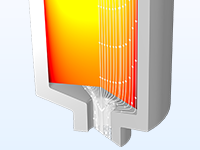

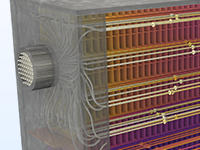

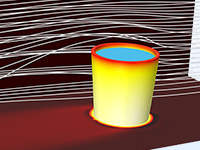

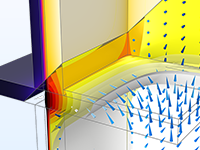

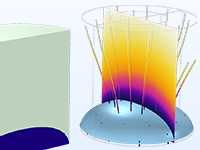

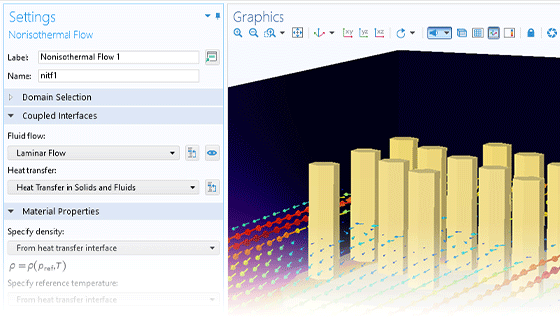

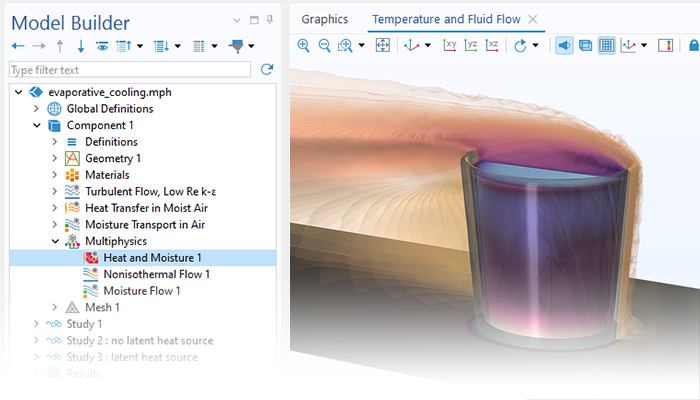

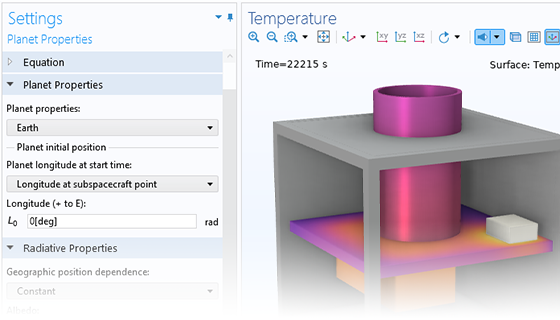

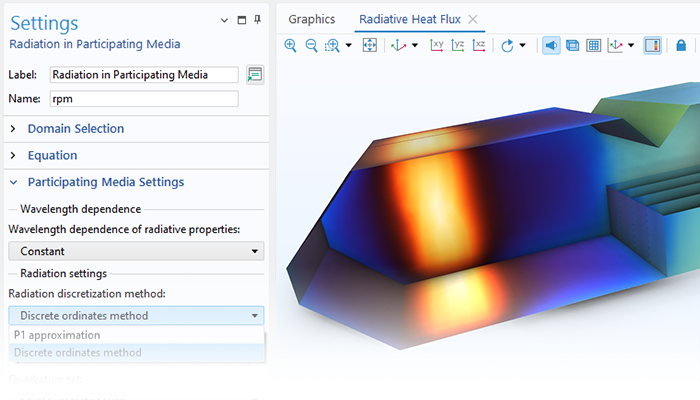

Alle Funktionen des Heat Transfer Module basieren auf den drei Arten des Wärmetransports: Leitung, Konvektion und Strahlung. Die Wärmeleitung in einem beliebigen Material kann eine isotrope oder anisotrope Wärmeleitfähigkeit haben, und sie kann konstant oder eine Funktion der Temperatur sein. Konvektion, die Bewegung von Fluiden in Wärmetransportsimulationen, kann erzwungene oder freie (natürliche) Konvektion sein. Die Wärmestrahlung kann durch Strahlung von Oberfläche zu Oberfläche oder durch Strahlung in halbtransparenten Medien berücksichtigt werden.

Es gibt viele Variationen innerhalb der einzelnen Formen des Wärmetransports, die zusammen berücksichtigt werden müssen- in einigen Fällen sogar alle drei gleichzeitig. Diese verschiedenen Wärmetransportformen erfordert verschiedene Gleichungen, die simultan behandelt werden müssen, um genaue Modelle zu gewährleisten. Das Heat Transfer Module bietet Modellierungsmöglichkeiten für jede Art von Wärmetransport.